Ceramic Factory for Special Vacuum System Scheme

1、 Brief introduction to the use of vacuum pumps in the customer’s factory

1. Vacuum pump pumping medium:

When the company produces ceramic products, the ceramic slurry moves the product bubbles in the mixing drum, and a vacuum pump is required to remove the bubbles, so that the ceramic slurry has good compactness.

2. Vacuum pump usage requirements:

According to the information provided by the customer, the company’s mixing machine design needs to be equipped with a water ring vacuum pump 2BV5121, with an air capacity of 3300Pa, a pumping speed of 280m3/h, and a power of 7.5kw.

3. Customer requirements and potential problems:

Currently, customers require the use of oil lubricated single stage rotary vane vacuum pumps to replace water ring pumps. The bubbles generated by the movement of ceramic slurry in the mixing drum also contain some water vapor, which is removed by a vacuum pump. If an oil lubricated vacuum pump is used, the water vapor in the extracted air will mix with the vacuum pump oil and cause a chemical reaction, leading to emulsification of the vacuum pump oil, thereby affecting the performance of the vacuum pump.

2、 Vacuum system options for vacuum pumps:

Single-stage rotary vane vacuum pump 2XZ: High limit vacuum, high pumping speed, low working noise, strong water vapor extraction ability, and environmental protection. The pump is equipped with an oil mist eliminator, which can remove 99.99% of the oil in the exhaust gas.

Optional rotary vane vacuum pump model 2XZ

Rated pumping speed: m3/h 302

Limit pressure: mbar 0.1

Noise dB (A): 75

Operating temperature ℃: 83

Oil consumption L: 7

Allowable pressure of water vapor mbar: 40

Water vapor extraction rate kg/h 5

Air inlet thread inch Rp2 ”

Rated power of motor kW 7.5

Rated speed of motor rpm 1440

Operating Weight kg 211

Overall dimension cm 101 × fifty-six × forty-four

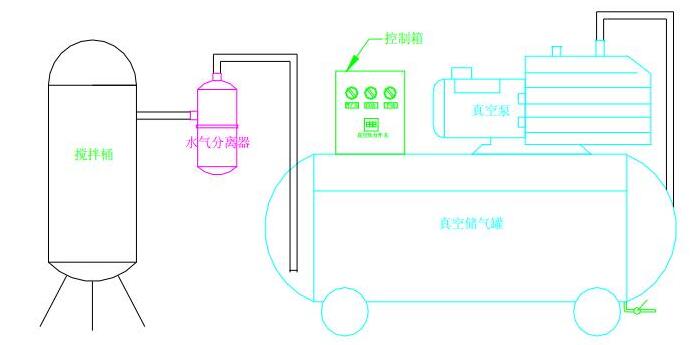

3、 Installation diagram of vacuum system in ceramic factory:

Vacuum system features:

1. With a control circuit, it controls the vacuum pump and vacuum air storage tank. A pressure range is set by the vacuum pressure gauge in the control box, and the vacuum degree in the air storage tank is controlled by the vacuum pressure sensor connected to the vacuum air storage tank. When the pressure in the vacuum reservoir is less than the set value, the vacuum pump starts. When the pressure in the vacuum reservoir reaches the set value, the vacuum pump stops running. Keep the vacuum in its air reservoir within a certain pressure range at all times.

2. A water vapor separator is installed between the pumped mixing drum and the vacuum gas storage tank to separate the moisture in the air extracted from the mixing drum.

3. The air storage tank is equipped with a drain valve, which can effectively drain the accumulated water in the vacuum air storage tank

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)