Granulation manufacturer’s environmental protection and energy-saving vacuum system

In recent years, with the promotion of environmental protection and energy conservation, many factories and processing plants that do not meet environmental protection standards have been greatly hit. Why do so many granulation plants encounter problems to analyze the current situation of granulation machine.

The water ring vacuum pump is widely used in the extrusion process in the granulation plant. The common configuration is one with one, that is, each granulator is equipped with one vacuum pump.

Water ring vacuum pump of impact:

1. Poor variety

a. Unstable vacuum degree, product burr, hollow, etc

b. Sheet stain, texture, color difference, etc

2. Energy waste: the efficiency of water ring vacuum pump itself is not high, and the operation loading rate is relatively low, resulting in energy waste

3. Low efficiency: the water ring vacuum pump is sensitive to water temperature. If it runs for a long time, it will cause insufficient vacuum degree and blowing force, which will seriously affect the production efficiency; When the temperature is high in summer, the problem is more obvious

4. Secondary pollution: the water ring vacuum pump needs water as the working fluid, and the waste residue generated in the granulation process is mixed with water, which brings environmental protection problems to the enterprise; In addition to the quality and energy consumption of plastic granulation, the waste water and environmental protection problems are also a major problem that enterprises need to solve urgently.

Energy saving scheme of environmental protection vacuum system of granulation manufacturer to introduction

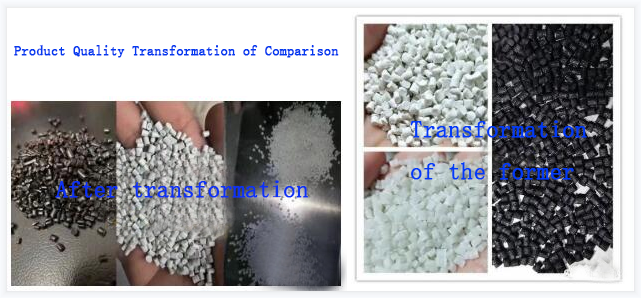

A plastic Co., Ltd. is an enterprise integrating R & D, production, dyeing, processing and sales of modified plastics. It has 8 granulation production lines. Originally, it used 8 sets of 2.2kW water ring vacuum pumps, and the vacuum degree can only be maintained at about – 0.5bar. In addition, it produces a large amount of waste water. The environmental pressure of the enterprise is very high, and the waste liquid cleaning work has not been effectively solved.

Through the professional vacuum transformation of EVP company, the centralized vacuum system is adopted, which breaks the tradition of one matching one extruder and saves about 50% of electricity and energy consumption for granulation enterprises; The vacuum degree is increased to -0.8bar;

Vacuum centralized supply is more stable, more convenient for management and lower maintenance cost; The automatic separation of waste liquid is realized, which effectively solves the problems of environmental protection and energy saving.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)