Applicatio of EVP Vacuum Pump in Coke Oven Gas Desulfurization Process

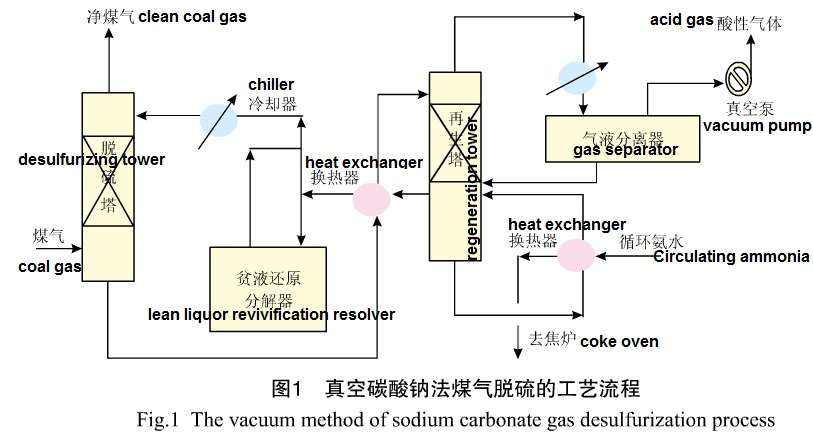

1.The vacuum method of sodium carbonate gas desulfurization process

The device for vacuum method of sodium carbonate gas desulfurization is including vacuum carbonate desulphuriztion and claus process recovery. Process show as Fig.1:

2.Vacuum pump selection

About coke oven gas desulfurization vacuum pump in steel plant, first of all,we need to take full consideration for the gas composition.Such as,dissolved gas specie,exhaust back pressure,inlet temperature,working liquid temperature and other specific indicators.Because these indicators are the factors that affect the ability of liquid ring vacuum pumps.Through the calculating these indicators analysis,we can get the standard state of liquid ring vacuum pump suction ability completely corrected value, follow-up correction value.Which can be selected the vacuum pumps that meet the design requirements.

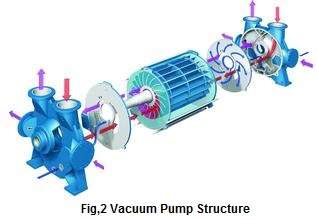

3.Vacuum pump structure

Vacuum pump system mainly includes the vacuum pump, three-phase motor, reducer, separator, heat exchanger, chassis and pipeline, etc. And the heart of system is vacuum pump.Below picture shows the vacuum pump structure.

4.Coke oven gas desulfurization vacuum pump selection requirements

Coke oven gas desulfurization vacuum pump in steel plant need to select single stage liquid ring vacuum pumps.Because the single stage liquid ring vacuum pump has simple structure,less spare parts,not easy to out of damage and low maintenance. During its whole working, It works smoothly and have small fluctuations.

The specific requirements of the coke oven gas desulfurization pump selection is as follows:

(1) The design of the vacuum pump performance to meet the requirements of the boost pressure and maximum flow parameters.

(2) The vacuum system under the condition of the environment temperature can normal operation and we don’t need to take additional measures to cool when in high temperature in summer season.

(3) Under the operating conditions requirements,the complete vacuum system unit can stable working,no abnormal noise and overheating phenomemon.

(4) The configuration of vacuum system unit need to easy repair and maintenance,the electrical wiring cables need to toward to the system outside so that the whole unit can easy maintenance and operation.

(5)The vacuum pump must be designed to ensure the gas-liquid separation efficiency,and for the tar be entrained gas conditions to special structure and size check, in order to facilitate the separation and discharge of the working fluid tar.

(6)Do not require deposition of tar into the heat exchanger,but to deposit in the separator and discharged directly.

(7)For the heat exchanger, to be able to ensure that even if the case of the deposition of tar heat exchangers can also be achieved within the required working fluid outlet temperature.

(8)Heat exchanger can be easy to clean.