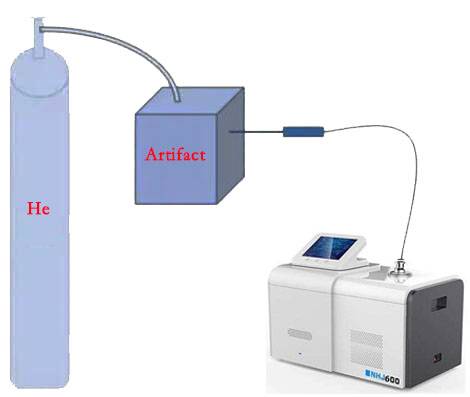

Vacuum leak detection with helium leak detectors

Using a helium leak detector to assist in detecting leaks in vacuum systems

Judgment of Vacuum System Leakage

The actual vacuum system cannot reach the predetermined limit vacuum for three reasons:

(1) Material release

(2) The pump is not working properly

(3) Vacuum system leakage

Reasons for Vacuum System Leakage

Vacuum system leakage is caused by various small gaps. (For example, in a glass vacuum system, there are small explosions of dirt and debris in the sintered area; in a metal vacuum system, there are welds and detachable parts; electric vacuum devices are mostly used in areas where metal and glass are sealed or metal ceramic are sealed, etc.)

The leakage of the vacuum system cannot be judged by the naked eye. Therefore, we can extract air from the vacuum system, reach a certain pressure, close the valve, isolate the system from the pump, and then measure the change in pressure. Distinguish the reason why the vacuum system cannot reach the maximum pressure by the pressure change curve. It is necessary to use certain methods to determine whether the vacuum system is leaking.

(1) The pressure of a remains unchanged at its original value. The container neither leaks nor releases air.

(2) The pressure started to rise quickly and later became saturated. The main explanation is for deflation.

(3) The straight increase in pressure indicates that the main cause is air leakage.

(4) The pressure of d starts to rise rapidly and then becomes higher, but there is no saturation, which is a combination of the above two situations, namely the simultaneous presence of deflation and leakage.

After determining the leak in the vacuum system, you can start searching for the location and size of the leak.

The size of the leakage hole is not a geometric dimension. Leakage holes in vacuum systems are usually very small and have complex shapes, making it difficult to express them using the geometric dimensions of the leakage hole. The essence of a leak is air leakage.

The size of the leakage hole: We usually use the leakage rate to express it. If the size and cross-section of several leakage holes can be different, but as long as the leakage rate (leakage rate) is equal, it is considered to be the same leakage rate: generally, it is expressed as the amount of gas leaked into the vacuum container by dry air flowing through the leakage holes at room temperature (20 ℃) and an external atmospheric pressure of 1.0133 * 105 Pa time unit: Q0=V · △ P/△ t

The units of leakage rate are trolls per second, millitrolls per second, atmospheric pressure milliliters per second is commonly used in semiconductor processes, and milligrams per year is commonly used in refrigeration engineering. At present, the pressure unit has been gradually changed to Pa, and the corresponding leakage rate unit is Pa · m3/s.

The determining factors of air leakage rate are:

(1) Geometric dimensions of leakage holes

(2) The pressure outside the container

(3) Types of gases

(4) Temperature and the flow state of gas in the leakage hole, etc