Best water ring vacuum pump principle structure and fault analysis

water ring vacuum pump structure and principle

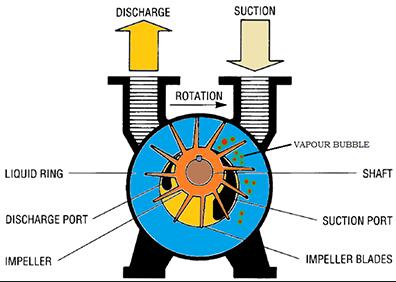

A certain amount of water is injected into the cylinder of the water ring vacuum pump, and the star impeller is installed in the cylinder eccentrically. When the impeller rotates, the water is thrown around by the centrifugal force to form a closed water ring which is eccentric to the impeller. The suction gas in the water ring vacuum pump enters the space between the water ring and the impeller through the suction hole along the suction pipe and joint. The crescent shaped part on the right side, because of the rotation of the impeller, the volume of the space gradually increases from small to large, so the vacuum suction gas. Water ring vacuum pump with the impeller rotation, gas into the left crescent part. Because the impeller rotates eccentrically, the space is gradually reduced, and the gas is gradually compressed and pressurized. The gas and water then enter the water tank along the exhaust pipe from the exhaust hole through the joint, and then are discharged from the vent pipe after automatic separation. The waste water and air in the water ring vacuum pump are discharged into the water tank together.

water ring vacuum pump fault analysis and solution:

1. Insufficient vacuum pump

Possible causes:

Insufficient power supply of motor leads to insufficient speed;

The gap between impeller and distribution plate is too large;

The mechanical seal is damaged, causing water leakage and air leakage;

Too much impeller wear;

Circulating water cannot be discharged.

Exclusion method:

Check whether the power supply voltage is within the rated voltage range of the motor;

Increase the water supply (it must be controlled within the correct range, otherwise the motor will be overloaded and heated);

Reduce the clearance between impeller and distribution plate (generally 0.15-0.20mm);

Replace the mechanical seal;

Replace the impeller;

Check the line at the water outlet.

2. It can’t be started or it’s noisy

Possible causes:

Motor supply voltage is insufficient;

Motor phase loss operation;

The pump is not used for a long time, resulting in corrosion;

Suction sundries in the pump;

Impeller drag distribution plate.

Exclusion method:

Check whether the power supply voltage is too low;

Check whether the motor wiring is firm;

If the pump is not used for a long time, rust remover can be added or the pump cover can be opened to remove the rust manually;

Open the pump cover to remove sundries;

Adjust the distance between impeller and distribution plate.

3. Motor overheating

Possible causes:

Excessive water supply leads to motor overload;

Motor phase loss;

The exhaust hole is blocked;

The impeller pulls other components.

Exclusion method:

Reduce the water supply to the normal range and check whether the wiring is firm;

Check the exhaust port;

Open the pump cover to adjust the clearance between the impeller and other components.

Water ring vacuum pump is widely used in coal mine (gas extraction), chemical industry, pharmaceutical industry, food, beer, building materials, machinery and other industries because of its easy maintenance and strong adaptability. In recent years, because of the implementation of centralized steam supply in the areas along the river and along the coast, the steam cost has increased. Most oil processing industries use water ring vacuum pump instead of more commonly used steam jet pump to achieve very good cost saving. (of course, the power consumption will also increase synchronously.).

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)