cryogenic pumps in semiconductor processes of important application

Basic principles and characteristics of cryogenic pumps

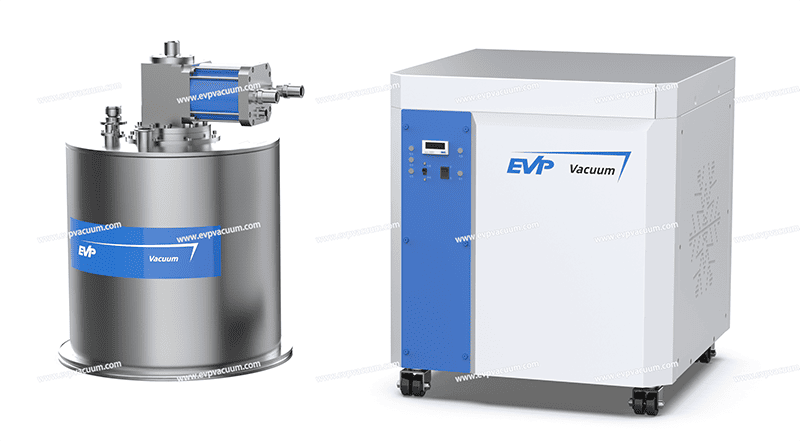

Cryogenic pumps is a technology that uses refrigeration technology to cool and condense the gas inside the pump into liquid or solid state, and adsorb them on the surface to achieve gas extraction. Compared with traditional mechanical pumps, cryogenic pumps have the following characteristics:

1. Cryogenic pumps can achieve higher vacuum levels.

2. The low-temperature pump will not generate a large amount of heat when extracting gas, and will not affect the extracted raw materials.

3. Cryogenic pumps can extract most gases.

Application of Cryogenic Pumps in Semiconductor Process

1. Low temperature sedimentation

Low temperature deposition technology is a new type of chemical vapor deposition technology. The areas and materials that need to be cleaned during the process can be directly pumped into the medullary canal for processing, avoiding the problems in traditional chemical vapor deposition technology.

2. Physical vapor deposition

Cryogenic pumps can also be used for physical vapor deposition to extract impurity gases such as oxygen from the pump, resulting in higher purity of the deposited material while avoiding damage to the deposited material.

The superiority of cryogenic pumps in semiconductor processes

1. High vacuum can be achieved in both low-temperature deposition and physical vapor deposition, resulting in purer deposited materials.

2. The operation of the low-temperature pump requires less power, so it can save electricity.

3. Due to the use of low-temperature pumps, there is no need for a thick cushion layer in the product manufacturing process, which can save costs more.

Epilogue

This article introduces the application of cryogenic pumps in semiconductor processes. With its advantages of high vacuum degree, high quality, and energy conservation, cryogenic pumps have gradually been widely used, providing new ideas for optimizing semiconductor processes.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)