double stage vacuum pump selection

How to choose a suitable double stage vacuum pump? It doesn’t mean that any vacuum pump can meet your working condition. Maybe your working condition needs oil-free and clean, or corrosion-resistant; another kind of vacuum pump can meet the conditions, but some need several combinations of vacuum pumps. So, in the selection process, what do we need to know?

Q: absolute pressure and relative pressure

Q: Calculation of pumping time of vacuum pump

Q: unit conversion of pumping rate of vacuum pump

Q: vacuum degree

Vacuum degree refers to the degree of gas thinness in vacuum state. If the pressure in the measured equipment is lower than atmospheric pressure, a vacuum gauge is required for pressure measurement. The value read from the vacuum gauge is called vacuum degree. The value of vacuum degree indicates that the actual value of system pressure is lower than atmospheric pressure, that is, vacuum degree = absolute pressure – atmospheric pressure, absolute pressure = atmospheric pressure + gauge pressure (vacuum degree).

I. main pump selection rules

1. Determine the type of main pump by limiting pressure;

2. Select the main pump for the required working pressure during process production;

3. Select the main pump according to the volume of the vacuum chamber and the required pumping time;

4. Correctly combine the vacuum pump;

5. Determine the oil type or oil-free type according to the requirements of clean vacuum;

6. Select the vacuum pump according to the composition characteristics of the extracted gas;

7. Select the main pump according to the economic indicators such as the initial investment and daily maintenance cost of the complete vacuum system.

II. How to select vacuum pre stage pump and pre pumping pump

1. It is related to the maximum discharge pressure of the main pump;

2. It is related to the gas flow discharged from the main pump;

3. Meet the requirements of pre pumping time and vacuum degree.

III. selection of vacuum pump – why to add maintenance pump sometimes

In order to avoid the back flow and oil vapor oxidation caused by the air leakage from the valve and the air release from the material surface, it is necessary for the front pump to continue to pump out the gas discharged from the main pump or set up a maintenance pump to discharge.

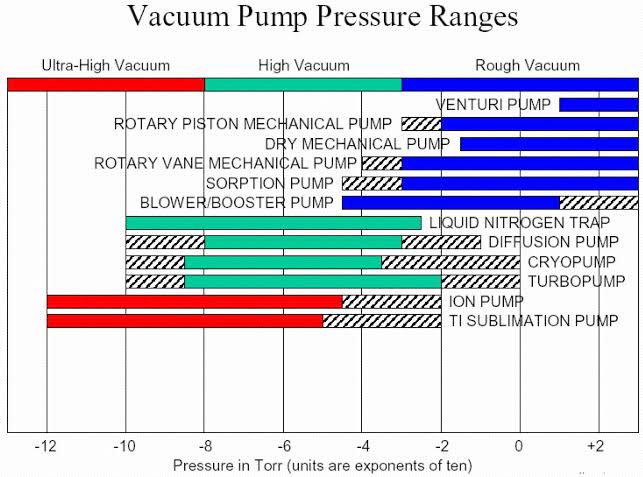

IV. working pressure range of common vacuum pumps

There are many kinds of vacuum pumps, different vacuum pumps have different vacuum performance. Some can work alone, some need the cooperation of the front pump to start, some need to reach a higher vacuum degree or pumping speed to form a vacuum unit and so on. Therefore, users need to select according to the production needs and characteristics of enterprises.

Common working pressure range and starting pressure of vacuum pump

Note: 1 × 105Pa is approximately equal to 1 standard atmospheric pressure; the data is collected for sorting, only within the normal range, and the actual data may change due to the specific brand or technical differences between the double stage vacuum pump manufacturers.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)