dry screw vacuum pump in cedar oil distillation

Successful cases of dry screw vacuum pump in cedar oil distillation application

One of our USA customer who are using the vacuum pump on a fractional distillation column in cedar oil industry and they have problems with the oil in our rotating vane pump becoming contaminated with process gasses.Soon after, the pump stops working.

To face this problem, customer asked help from us and requested a new solutions or replace solution pump for their case. The requested vacuum is at least a 1 mmHg vacuum and 100ACFM.Their previous pump used a Busch R5, 5HP and it never works. Because, their process produces steam and oil vapors that can get into the pump. Will these contaminants cause a problem.

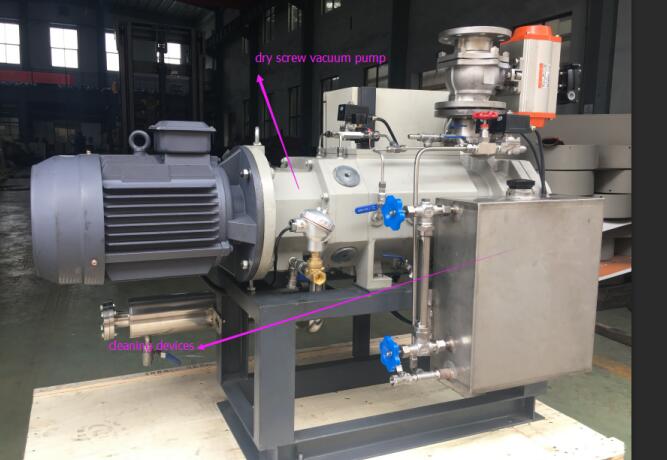

After knowing all their requirements and their worried things, the most suitable pump which we recommended was Dry screw vacuum pumps. The working vacuum absolute meet customer’s requirements. The biggest problems is their process gases with vapor will go into the pump chamber to result the pump broken or regularly maintains. Now, we add a cleaning devices on the dry screw vacuum pump side which will completely resolve their problems.

The cleaning devices main parts is a tank which can contain the acetone (as customer’s process is cedar oil will adhere to the pump chamber together with the vapor,so we recommend this solvent, of course, it can also contain the other solvents depending on different applications), electric control box and valves & pipelines. For details, please check below picture: