Exploring Vacuum Systems: From Equipment Combinations to Application Scenarios, Understand the Construction of Vacuum Environments in One Article

In modern industry, scientific research, and high-end manufacturing, the construction of a vacuum environment is fundamental to the realization of many key technologies. The vacuum requirements vary significantly across different scenarios, from low-vacuum applications in conventional industries to ultra-high-vacuum precision scientific research, necessitating the use of vacuum equipment based on specific principles and scientific combinations. This article will systematically analyze the core types of vacuum equipment and their classification into vacuum levels, and delve into typical equipment combination schemes in practical applications, providing a scientific reference for understanding vacuum technology.

Vacuum Equipment: Principles, Levels, and Characteristics

Vacuum equipment is designed based on different gas extraction principles, and its applicable vacuum levels, core features, and application scenarios vary significantly. The following is a detailed analysis of seven types of core vacuum equipment:

1.Working Principle of Mechanical Pumps: Mechanical pumps change the volume of the pump chamber through the movement of mechanical structures (such as vane rotation and screw engagement), achieving gas intake, compression, and exhaust. They are the most basic pumping equipment in vacuum systems. Core Sub-types:

* **Rotary Vane Pump:** Relies on rotating vanes within the pump chamber and the stator inner wall to form a variable volume chamber, completing gas compression. It has a compact structure and low cost.

* **Screw Pump:** Uses two meshing screws rotating at high speed to push gas from the intake end to the exhaust end. It has strong pumping stability and is suitable for scenarios containing small amounts of dust or condensable gases.

Applicable Vacuum Levels: Low vacuum (10⁵~10² Pa) to medium vacuum (10²~10⁻¹ Pa).

Core Features: The pumping range covers atmospheric pressure to medium vacuum. It is typically used as a “backing pump” (pre-pump) to provide the initial vacuum environment for high vacuum equipment and is the “startup foundation” for most vacuum systems.

2.Diffusion Pumps Working Principle: By heating specialized diffusion pump oil within the pump, a high-speed oil vapor jet (reaching speeds of hundreds of meters per second) is generated. Utilizing the jet’s ability to carry gas molecules, the gas is propelled from the vacuum chamber to the outlet, where it is then discharged by the backing pump. Equipment Dependence: It cannot be started directly from atmospheric pressure; it must be used in conjunction with a mechanical pump (such as a rotary vane pump). The mechanical pump must first reduce the system pressure to below 10⁻¹ Pa before the diffusion pump can be started. Applicable Vacuum Levels: High vacuum (10⁻¹~10⁻⁶ Pa). Key Features: No moving mechanical parts, stable operation, and high pumping speed; however, a cooling system (such as a water-cooled jacket) is required to condense the oil vapor, and the oil vapor may cause slight contamination of the vacuum chamber, making it unsuitable for scenarios requiring extremely high cleanliness.

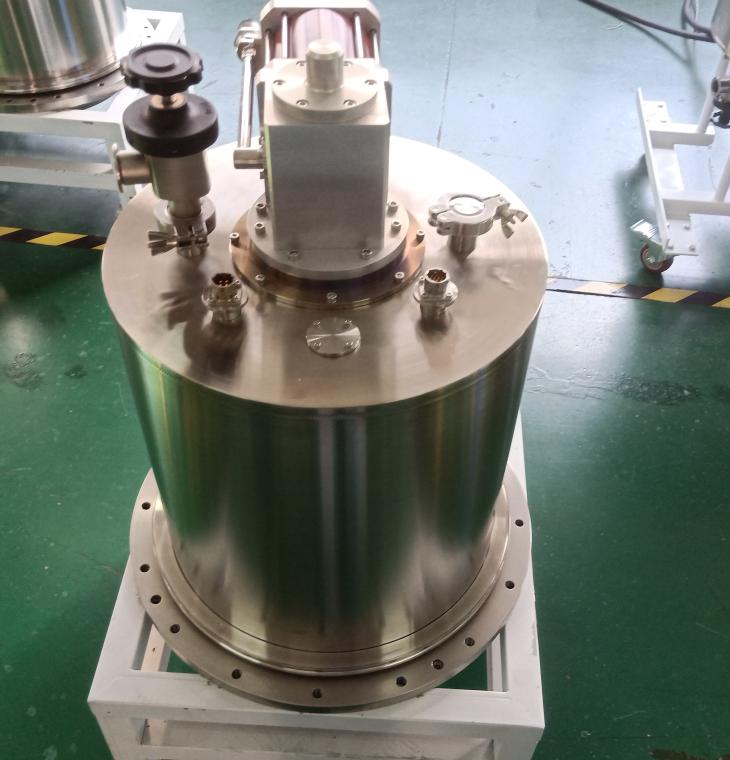

3.Working principle of a turbomolecular pump: The pump chamber contains multiple layers of high-speed rotating blades (speed up to 10⁴~10⁵ rpm). These blades alternate with stationary stator blades. The high-speed rotating blades collide with gas molecules, “pushing” them towards the outlet, thus extracting the gas. Equipment dependence: Requires a backing mechanical pump (such as a rotary vane pump or screw pump). The backing vacuum must reach below 10⁻² Pa to prevent damage to the high-speed blades due to excessive gas resistance. Applicable vacuum levels: High vacuum to ultra-high vacuum (10⁻⁴~10⁻¹¹ Pa). Key features: Oil-free design, eliminating oil vapor contamination and ensuring high gas cleanliness; fast response speed and precise vacuum control, making it a core piece of equipment in semiconductor manufacturing, precision instruments (such as electron microscopes), and scientific research.

4.Ion Pumps Working Principle: A strong electric field formed by the anode and cathode ionizes gas molecules within the vacuum chamber. The resulting positive ions collide with the titanium cathode under the influence of the electric field, are adsorbed by the cathode, and form stable compounds, thus achieving gas “capture.” Equipment Dependence: Requires use in conjunction with a turbomolecular pump. The pump reduces the system pressure to below 10⁻⁷ Pa to ensure ionization efficiency and prevent rapid saturation of the cathode due to excessively high gas concentration. Applicable Vacuum Level: Ultra-high vacuum (10⁻⁷~10⁻¹² Pa). Key Features: No moving mechanical parts, vibration-free and noiseless operation; extremely high vacuum stability, but relatively low pumping speed, suitable only for “maintaining ultra-high vacuum” scenarios, not for rapid gas extraction.

5.Cryopumps Working Principle: Cryopumps utilize a cryogenic pump or liquid helium to achieve ultra-low temperatures in the pump’s internal “cold head” (liquid helium cold head temperature approximately 4.2 K, cryogenic pump cold head approximately 10~20 K). Gas extraction is achieved through the condensation of gas molecules on the cold head surface (e.g., H₂O, N₂) or physical adsorption (e.g., He, H₂). Key Operation: Periodic “regeneration” is required—the cold head is heated to release the adsorbed gas, which is then discharged by the backing pump, restoring the cold head’s adsorption capacity. Applicable Vacuum Level: Extremely high vacuum (10⁻⁷~10⁻¹³ Pa). Core Features: Extremely high pumping speed (especially for easily condensable gases such as water vapor and nitrogen), no oil contamination; however, the regeneration process requires interrupting system operation, and the operating cost of liquid helium cryogenic pumps is relatively high.

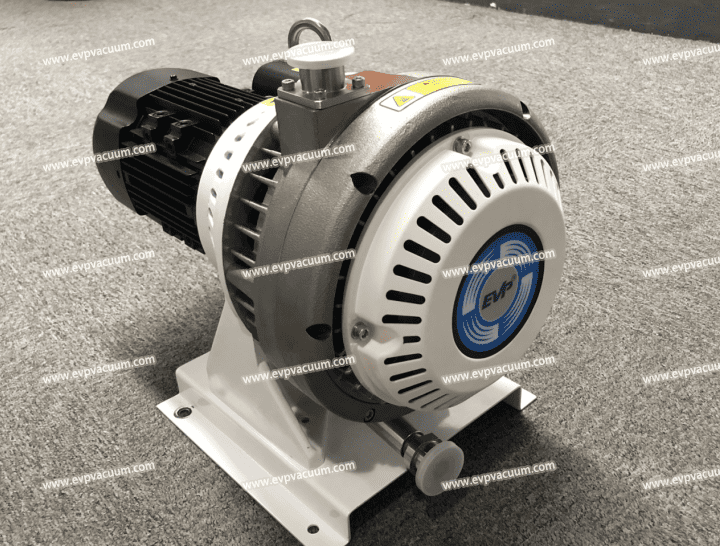

6.Dry Pumps Working Principle: Employing an oil-free sealing design, they compress gas through mechanical motion using claw, vortex, or diaphragm structures, avoiding oil vapor contamination common in traditional oil-sealed pumps. Applicable Vacuum Levels: Low to medium vacuum (10⁵~10⁻² Pa). Key Features: Clean operation, no oil maintenance required; strong corrosion resistance, capable of handling environments containing small amounts of corrosive gases, widely used in industries with high cleanliness requirements such as semiconductors, pharmaceuticals, and food processing.

Vacuum Levels and Application Scenarios According to international standards, vacuum environments are classified into low vacuum, medium vacuum, high vacuum, ultra-high vacuum, and extremely high vacuum based on pressure range. Different levels correspond to different technical requirements and application fields, as shown in the table below:

| vacuum level | Pressure range(Pa) | Typical application scenarios |

| low vacuum | 10⁵~10² | Vacuum suction cups, vacuum packaging, vacuum filtration, freeze drying |

| Medium vacuum | 10²~10⁻¹ | Vacuum coating (primary), vacuum heat treatment, vacuum impregnation, mass spectrometry (primary gas extraction) |

| high vacuum | 10⁻¹~10⁻⁶ | Precision vacuum coating (such as optical thin films), electron beam welding, vacuum melting, semiconductor etching (initial stage) |

| Ultra-high vacuum | 10⁻⁶~10⁻¹⁰ | Surface science research (such as atomic force microscopy), molecular beam epitaxy, semiconductor ion implantation, high-resolution mass spectrometry |

| Super Ultra-high vacuum | <10⁻¹⁰ | Quantum computing experiments, space environment simulation, ultra-low temperature physics research, precision particle detectors |

Typical Vacuum System Combinations: A single vacuum device cannot cover the full range of requirements from atmospheric pressure to ultra-high vacuum. In practical applications, a multi-stage series combination of “backup pump → main pump → auxiliary pump” is needed to gradually increase the vacuum level. The following are six of the most common combination schemes, covering different vacuum requirement scenarios:

1.Two-Stage Rotary Vane Vacuum Pump Combination

Combination Structure: Consists of two rotary vane pumps connected in series. The first stage pump draws gas from atmospheric pressure, reducing the pressure to 10⁰~10⁻¹ Pa. The second stage pump further compresses the gas, reducing the pressure to its ultimate value. Ultimate Vacuum: 10⁻²~10⁻³ Torr (1 Torr = 133.322 Pa, approximately 1.3 × 10⁰~1.3 × 10⁻¹ Pa).

Advantages: Simple structure, low cost, no need for additional pumps, can independently achieve extraction from atmospheric pressure to medium-low vacuum, suitable for applications with low vacuum requirements (such as vacuum drying, evacuating small vacuum containers).

Disadvantages: Lower ultimate vacuum, unable to meet high vacuum requirements; relies on oil seals, oil vapor may contaminate the system; in high-temperature or corrosive gas environments, the performance of the rotary vane seal is prone to degradation, shortening its lifespan.

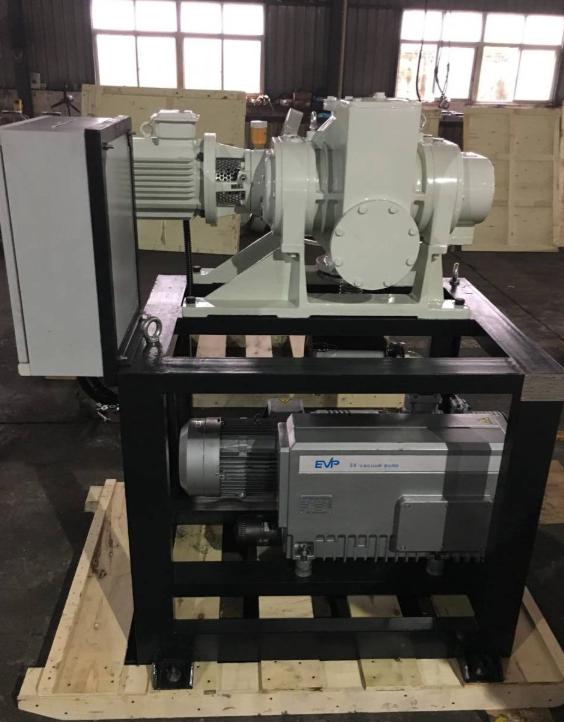

2.Combination Logic of Rotary Vane Vacuum Pump + Roots Vacuum Pump: The rotary vane pump acts as the backing pump, responsible for reducing the system pressure from atmospheric pressure to 10⁻¹~10⁻² Pa; the Roots vacuum pump acts as the main pump, utilizing the “volume amplification” effect of the synchronous counter-rotating dual rotors to further reduce the pressure to the high vacuum range. Ultimate vacuum: 10⁻² Pa.

Applicable Scenarios: Vacuum metallurgy, vacuum heat treatment of power capacitors/transformers, evacuation of large vacuum chambers (such as vacuum coating machines).

Advantages: Fast pumping speed, enabling continuous pumping from atmospheric pressure to high vacuum, adaptable to various industrial processes; the Roots pump has no internal compression, making it highly adaptable to different gas types.

Disadvantages: The rotary vane pump is an oil-sealed design, which may introduce oil vapor contamination, requiring an additional cold trap or oil mist filter; the system is relatively large, requiring sufficient installation space.

3.Combination Logic of Water Ring Vacuum Pump + Roots Vacuum Pump: The water ring vacuum pump acts as the backing pump, utilizing the volume change of the “water ring” within the pump chamber to achieve rough pumping, reducing the pressure to 10³~10² Pa. The Roots vacuum pump acts as the main pump, further reducing the pressure and compensating for the low ultimate vacuum of the water ring pump. Ultimate vacuum: 25 Pa.

Applicable Scenarios: Chemical industry (e.g., solvent recovery), pharmaceutical industry (e.g., vacuum distillation), food processing (e.g., vacuum degassing), wastewater treatment aeration systems.

Advantages: The water ring pump has an oil-free design, ensuring clean operation and handling scenarios containing small amounts of condensable gases; the system has strong corrosion resistance and is suitable for humid and dusty industrial environments.

Disadvantages: Lower ultimate vacuum, only suitable for medium to low vacuum requirements; the water ring pump requires continuous replenishment of circulating water, and wastewater may be generated during operation, requiring supporting water treatment equipment.

4.Two-stage Roots vacuum pump combination. Two-stage Roots pump combinations are available in series and parallel configurations to suit different pumping speed and vacuum requirements: (1) Series Roots vacuum pump combination logic: Two-stage Roots pumps are connected in series. The first-stage Roots pump starts pumping from a basic vacuum of 10⁻¹ Pa provided by the pre-stage pump (usually a rotary vane pump), reducing the pressure to 10⁻³ Pa. The second-stage Roots pump further compresses the pressure to achieve a higher vacuum. Ultimate vacuum: 10⁻³~10⁻⁴ Torr (approximately 1.3×10⁻¹~1.3×10⁻² Pa).

Applicable scenarios: Semiconductor manufacturing (e.g., drying after wafer cleaning), vacuum coating (e.g., metal thin film deposition), vacuum metallurgy (e.g., rare metal purification).

Advantages: Can achieve a high vacuum, stable pumping speed, and strong adaptability to gas load fluctuations. Disadvantages: High cost; strict requirements for synchronous control of the two-stage pumps; strong dependence on the back pump; insufficient vacuum in the back pump can lead to overload damage to the Roots pump. (2) Parallel Roots Vacuum Pump Combination Logic: Two or more Roots pumps are connected in parallel, sharing the same inlet and outlet. The total pumping speed is increased by “multiple pumps pumping at the same time”. The back pump is usually a screw pump or a rotary vane pump. Ultimate Vacuum: Comparable to a single-stage Roots pump (approximately 10⁻¹~10⁻² Pa), but the pumping speed is 1.5~2 times that of a single pump (the airflow interference between pumps needs to be considered). Applicable Scenarios: Pneumatic conveying (such as vacuum feeding of granular materials), rapid rough pumping of large vacuum containers (such as aerospace simulation cabins), sewage treatment aeration systems. Advantages: High pumping speed, which can significantly shorten the rough pumping time of large cavities; when a single pump fails, other pumps can continue to operate, and the system has high reliability. Disadvantages: No improvement in ultimate vacuum level; only suitable for scenarios requiring high pumping speed and low vacuum level; precise design of airflow distribution between pumps is required, otherwise “airflow dead zones” can easily occur, reducing pumping efficiency.

5.Roots Vacuum Pump + Diffusion Pump Combination Logic: The Roots pump acts as the backing pump, reducing the system pressure from atmospheric pressure to below 10⁻¹ Pa, providing the starting conditions for the diffusion pump; the diffusion pump acts as the main pump, using an oil vapor jet to reduce the pressure to the high vacuum range. Ultimate vacuum level: 10⁻⁷ Torr (approximately 1.3 × 10⁻⁵ Pa).

Applicable Scenarios: High vacuum coating (such as anti-reflective coatings for optical lenses), vacuum brazing, electron tube manufacturing, and basic vacuum experiments in scientific research.

Advantages: High pumping speed, able to quickly reach high vacuum; the diffusion pump has no moving mechanical parts, ensuring stable operation and low maintenance costs.

Disadvantages: Diffusion pumps generate significant heat during operation, requiring a water-cooling system; oil vapor may flow back into the vacuum chamber, contaminating precision components (such as optical lenses), necessitating the use of oil baffles or cold traps.

6. Roots Vacuum Pump + Turbomolecular Pump Combination: Combination Logic: The Roots pump acts as the backing pump, reducing the system pressure to below 10⁻² Pa; the turbomolecular pump acts as the main pump, utilizing high-speed blades to impact gas molecules, achieving ultra-high vacuum extraction. In some scenarios, an ion pump is additionally used to maintain the vacuum level. Ultimate Vacuum: 10⁻¹⁰ Torr (approximately 1.3 × 10⁻⁸ Pa).

Applicable Scenarios: Surface science research (e.g., X-ray photoelectron spectroscopy), mass spectrometry (high-resolution detection), semiconductor chip manufacturing (e.g., atomic layer deposition), quantum device development.

Advantages: Oil-free, extremely high vacuum cleanliness; stable pumping speed, precise vacuum control, suitable for precision scientific research and high-end manufacturing needs.

Disadvantages: High cost (the unit price of a turbomolecular pump is usually 5 to 10 times that of a diffusion pump); high maintenance requirements, as the high-speed blades are extremely sensitive to dust and metal particles, and the cleanliness of the intake air must be strictly controlled; sensitive to fluctuations in power supply voltage and ambient temperature, requiring the use of voltage stabilization and temperature control equipment.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)