Brand: EVP

Classification: Flapper valve category

Availability : In Stock

Gdq-j-a series normally closed pneumatic high vacuum flapper valve relies on compressed air as the valve plate opening and closing power through the electromagnetic reversing valve.

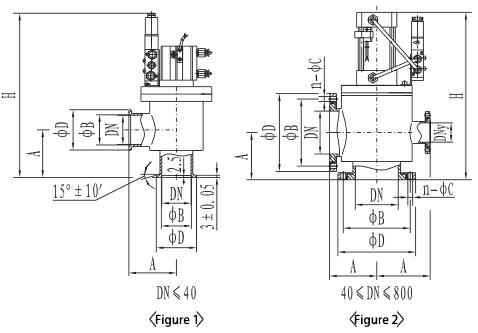

Dimensions

(Figure 1) (KF) connection and external dimensions

| model | Path (DN) | ΦD | ΦB | H | A | Flange standard |

| GDQ-J10/KF | 10 | 30 | 12.2 | 180 | 30 | GB4982 |

| GDQ-J16/KF | 16 | 30 | 17.2 | 180 | 40 | |

| GDQ-J25/KF | 25 | 40 | 26.2 | 200 | 50 | |

| GDQ-J40/KF | 40 | 55 | 41.2 | 210 | 65 | |

| GDQ-J50/KF | 50 | 75 | 52.2 | 276 | 70 | / |

(Figure 2) Looper flange connection and overall dimensions

| model | Path (DN) | ΦD | ΦB | H | A | n-ΦC | Flange standard | DNy (pre-extraction port) |

| GDQ-J40A | 40 | 100 | 80 | 230 | 70 | 4-Φ9 | GB/T6070 | / |

| GDQ-J50A | 50 | 110 | 90 | 276 | 70 | |||

| GDQ-J63A | 63 | 130 | 110 | 283 | 88 | |||

| GDQ-J80A | 80 | 145 | 125 | 324 | 98 | 8-Φ9 | ||

| GDQ-J100A | 100 | 165 | 145 | 338 | 108 | |||

| GDQ-J125A | 125 | 200 | 175 | 424 | 128 | 8-Φ11 | ||

| GDQ-J(S)150A | 150 | 220 | 195 | 482 | 138 | JB919 | KF40(GB4982) | |

| GDQ-J(S)160A | 160 | 225 | 200 | 482 | 138 | GB/T6070 | ||

| GDQ-J(S)200A | 200 | 285 | 260 | 620 | 200 | 12-Φ11 | DN50(GB/T6070) | |

| GDQ-J(S)250A | 250 | 335 | 310 | 655 | 208 | DN63(GB/T6070) | ||

| GDQ-J(S)300A | 300 | 380 | 350 | 783 | 250 | 8-Φ14 | JB919 | DN80(GB/T6070) |

| GDQ-J(S)320A | 320 | 425 | 395 | 1064 | 250 | 12-Φ14 | GB/T6070 | |

| GDQ-J(S)400A | 400 | 510 | 480 | 1210 | 330 | 16-Φ14 | DN100(GB/T6070) | |

| GDQ-J(S)400A | 400 | 500 | 465 | 1210 | 330 | 8-Φ18 | JB919 | |

| GDQ-J(S)500A | 500 | 610 | 580 | 1270 | 360 | 16-Φ14 | GB/T6070 | DN125(GB/T6070) |

| GDQ-J(S)600A | 600 | 710 | 670 | 1562 | 450 | 12-Φ21 | JB919 | DN160(GB/T6070) |

| GDQ-J(S)630A | 630 | 750 | 720 | 1562 | 450 | 20-Φ14 | GB/T6070 | |

| GDQ-J(S)800A | 800 | 920 | 880 | 1865 | 550 | 20-Φ21 | JB919 | DN200GB/T6070) |

Gdq-j-a series normally closed pneumatic high vacuum flapper valve relies on compressed air as the valve plate opening and closing power through the electromagnetic reversing valve. When the power supply or compressed air is lost, the valve with a diameter of less than DN80 will automatically close the valve by the spring force. The valve with a diameter of more than DN100 will quickly close the original air source pressure of the cylinder through the solenoid valve group to automatically close the valve. So as to achieve the function of quickly cutting off the air flow in the vacuum system. The shaft seal structure of pneumatic high vacuum flapper valve can be divided into gdq-j-a rubber seal and gdq-j-a (b) bellows seal. Gdq-j type is angle type, gdq-s type is tee type with pre extraction port.

The applicable working medium is air and non corrosive gas.

Technical Parameters

| applicability(Pa) | 105~1.3×10-4 (Shaft seal material is rubber) |

| 105~1.3×10-6 (Shaft seal material is bellows) | |

| Valve leak rate(Pa.L/S) | ≤1.3×10-5 (the shaft seal material is rubber) |

| ≤1.3×10-7 (Shaft seal material is bellows) | |

| Applicable temperature(℃) | -25~+80 (The sealing material is nitrile rubber) |

| -30~+150 (the sealing material is fluorine rubber) | |

| Material of main parts of valve | Stainless steel or carbon steel |

| Air source pressure (Mpa) | 0.4~0.8 |

| Installation position | DN<300 arbitrary, DN≥300 vertical |

| supply voltage | Standard factory: AC220V/50Hz |

| Special designation: ①AC110V; ②DC24V; ③DC12V, etc. | |

| Signal feedback | Standard factory: without feedback signal |

| Special designation: Magnetic switch DC/AC5~240V |

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.