Helium mass spectrometer leak detector used for leak detection of transformer components

Leak detection requirements for transformer components

A domestic manufacturer produces high-quality insulation components for medium and high voltage current, voltage transformers, and switchgear, with voltage levels ranging from 3.6 to 40.5kV. Annual production capacity of 120000 units. For domestic medium voltage transformer enterprises. Mainly providing supporting services for domestic switch companies, domestic electrical control companies, domestic and foreign switch cabinet manufacturers in Malaysia, Australia, South Africa, and a small number of other customers.

The customer’s product has high requirements for insulation and sealing, among which sealing is very important for maintaining the insulation oil and insulation performance Insulation is ensured through materials and insulating oil, and sealing plays a decisive role in the durability and insulation performance of the product after 5 years.

The customer has been using flaw detection machines for quality defect detection, but they are powerless to detect minor cracks and leaks The company requires the use of a helium mass spectrometer leak detector to measure a leak rate value as the standard

The helium mass spectrometer leak detector is easy to use, with accurate and reliable data, and a beautiful appearance; Small size; Lightweight; Internal modular design, easy to detect and maintain; Easy to use, one click operation; Permission setting ensures that the permissions of operators and managers are different, preventing accidental changes to the set parameters

Leak detection operation of transformer components

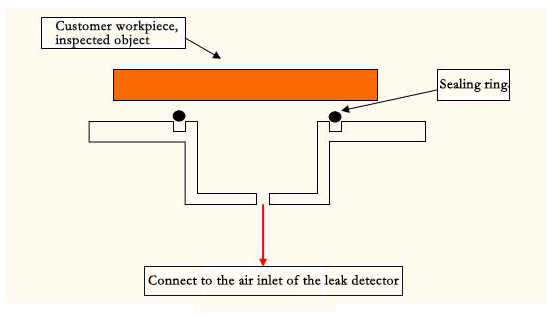

Helium mass spectrometer leak detector diagram:

The customer’s inspected object is a flat workpiece with some metal parts embedded in resin material. Now it is necessary to check whether there is any air leakage on the entire flat plate. The leak detection diagram is as follows:

The actual operation is as follows:

(1) Install the workpiece on the fixture and start the helium mass spectrometer leak detector

(2) Spray helium gas (He) between the metal parts and resin on the workpiece (suspected leakage area), observe the leakage rate value on the helium mass spectrometer leak detector, and record it if necessary

(3) After the leak detection is completed, stop the helium mass spectrometer leak detector and remove the workpiece