Let your vacuum equipment work healthily and happily

A key feature of a diffusion pump is that it is durable and will last for many years if used and maintained properly.

Be sure to use original pump oil

The spray tower and heating power of the diffusion pump are designed for special oil products, and its performance parameters such as pumping speed and ultimate vacuum are also tested when using original company oil products. Using non-original oil products will affect our understanding of the diffusion pump. It is also not conducive to our engineers to troubleshoot, because different brands or batches of third-party pump oil components may have large differences, which may cause insufficient pumping speed/ultimate vacuum, crystallization, coking, Problems such as oil return, in serious cases, may even cause dangers such as explosions during improper operation.

Pay attention to the oil level and the color of the oil

The color of the oil should be colorless or highly transparent reddish-brown. When the color of the oil becomes dark and black, it should be replaced in time.

If a large amount of dust is generated in the process, especially when a large amount of particles can be observed in the discharged pump oil, there is likely to be a large amount of sediment in the oil pool of the diffusion pump, which will have a serious impact on the normal operation of the pump , please remove these deposits and thoroughly clean the diffusion pump every time you change the oil.

The temperature protection switch must be connected to the control system

Most models of EVP diffusion pumps are equipped with a temperature protection switch on the pump body. When the temperature of the diffusion pump is abnormal due to insufficient cooling, insufficient oil level, etc., a timely signal can be given. When designing the control system, the temperature protection switch (normally closed dry contact) must be connected to the system and interlocked with the power supply of the diffusion pump heater to protect the diffusion pump.

Do not turn on and off the heater frequently

The diffusion pump works by the oil vapor generated by the continuous vaporization of the pump oil. The vaporization amount of the pump oil and the kinetic energy of the injection are directly proportional to the power of the heater. The oil temperature when the diffusion pump works normally is determined by the physical characteristics (boiling point) of the oil itself. The pump should continue to work at the boiling point temperature. If the heating of the pump oil is stopped, the diffusion pump will quickly lose its air-carrying capacity, causing the pumping speed to decrease. The drop and oil return increase; therefore, do not control the oil temperature by frequently turning on and off the heater. In addition, frequent power on and off will make the heater hot and cold, which will seriously affect its life.

Pay attention to monitor the status of the heater

When a heater burns out, there may be problems such as pumping speed, vacuum degree drop, and oil return. It is necessary to monitor the working status (current/power) of the diffusion pump heater so as to detect abnormalities in time.

When replacing heaters, be sure to use original Agilent heaters of the same wattage and voltage rating. When installing the heater, the heater and the bottom plate of the pump must be closely attached. If there is a gap between the two, it will cause poor heat conduction of the heater, and the local temperature will be too high, which will seriously affect the life of the heater. Some models of diffusion pump heaters are designed with a one-time elastic pressure plate (Crush plate), which will produce permanent deformation and fit closely with the heater when it is pressed, so that the temperature of the heater is more uniform and the life span is longer. These models When replacing the heater of the diffusion pump, the pressure plate should also be replaced at the same time.

Cooling water, flow is more important than pressure

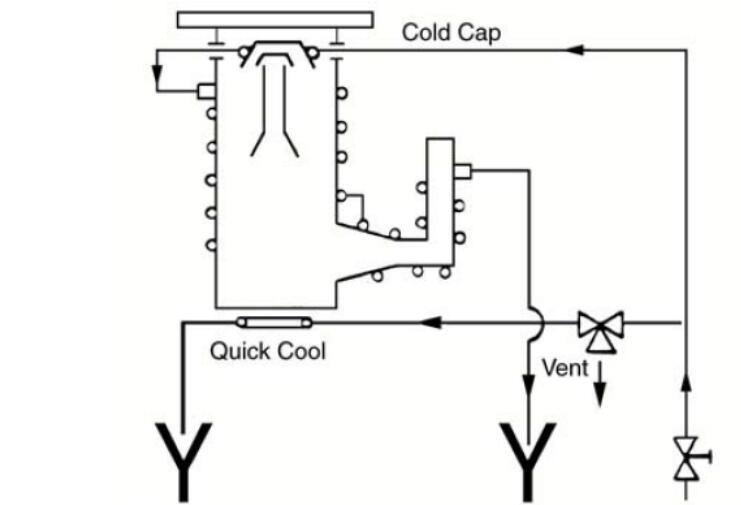

The pump wall of a large diffusion pump is generally cooled by cooling water. Many customers will monitor the inlet pressure of the cooling water. However, when the cooling coil is blocked or partially blocked, the cooling effect will not change even if the inlet pressure does not change. As long as the flow of cooling water is guaranteed, the change of cooling water pressure has little effect on the cooling effect; therefore, monitoring the flow of cooling water is more important than monitoring its pressure. In addition, the connection method of cooling water is different from that of some equipment, which enters from the bottom and goes out from the top. The cooling water of the diffusion pump enters from the air inlet and exits from the exhaust port. It must be connected according to the diagram in the manual.

To reduce oil return, the following points are also critical

The higher the working pressure of the diffusion pump, the more serious the oil return. The Agilent diffusion pump has a higher pumping speed when the high valve is just opened (a few Pa to a few tenths of a Pa), which will greatly reduce the pumping time in this pressure section, thereby reducing the total oil return.

Do not allow the diffusion pump to handle an air load that exceeds its maximum displacement. Each diffusion pump has a maximum air load parameter. The total air load handled by the diffusion pump during operation cannot exceed this value, otherwise serious oil return will occur .

High valve opening pressure is particular. At the moment the high valve is opened, the gas load originally handled by the roughing pump will be switched to the diffusion pump. Assuming that the high valve is opened when the system air load is equal to the maximum air load of the diffusion pump, the formula Q= P*S can calculate the opening pressure; it can be seen that the greater the pumping speed of the roughing pump used, the lower the pressure to open the diffusion pump.

If the exhaust valve is closed intermittently, do not directly close the valve of the exhaust port of the diffusion pump when the front pump is switched to rough pumping of the cavity, or the system is in standby mode. It is better to use the maintenance pump to continuously pump the exhaust port of the diffusion pump. Keep its pressure lower than the maximum exhaust pressure that the diffusion pump can withstand (usually tens of Pa).

Reinforced cold cap can be added when a lower oil return rate is required. Reinforced cold cap can be added. EVP provides a reinforced cold cap that can be built into the diffusion pump, which can reduce the oil return rate by more than 90% without increasing the height of the pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)