Vacuum Units in Short Path Distillation Applications of Importance

Many materials are often heat-sensitive, viscous and/or have high boiling point properties, such as heavy petroleum residues, chemicals, medicines and natural foods, health products, fatty acids, etc. If we want to separate and purify the components of these materials It is necessary to maintain the quality of the product, but also to ensure that thermal decomposition or polymerization is minimized, thereby eliminating damage to the product. In this process, the purification of raw materials or finished products is very critical. The purification method depends on different raw materials, and the precision of distillation and purification is very important.

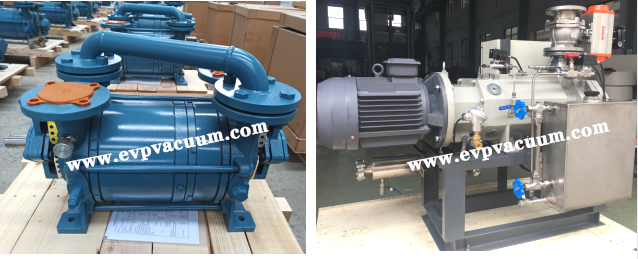

The principle and characteristics of short-path distillation are that the pressure difference between the boiling film and the condensing surface is the driving force for the flow of steam, and a small pressure drop will cause the flow of steam. In a short residence time: the function of the film scraper makes the residence time of the liquid film on the heating surface extremely short. At low steam room temperature, because the condenser is located directly opposite the heating surface, the pressure difference is reduced, so a vacuum unit with high energy efficiency is required to maintain a very high degree of vacuum, so that the material can be kept at a very low temperature without even needing to The boiling point is the steam house. The vacuum pump unit produced by Shanghai EVP Vacuum Technology Co., Ltd. plays the most critical step in the short-path distillation process.

Operation at 1 mbar requires a very short distance between the boiling surface and the condensing surface, and the evaporator made based on this principle is called a short-path evaporator. The short-path evaporator (molecular steam house) has a built-in condenser opposite the heating surface and reduces the operating pressure to 0.001mbar. The short-path evaporator is a thermal separation technology process that works under the pressure of 1~0.001mbar. It has a lower boiling temperature and is very suitable for heat-sensitive and high-boiling materials.

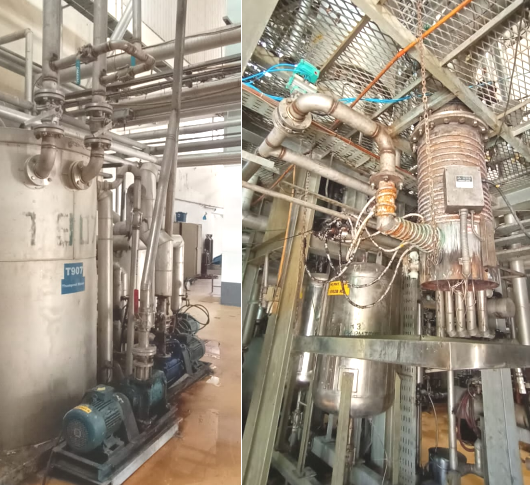

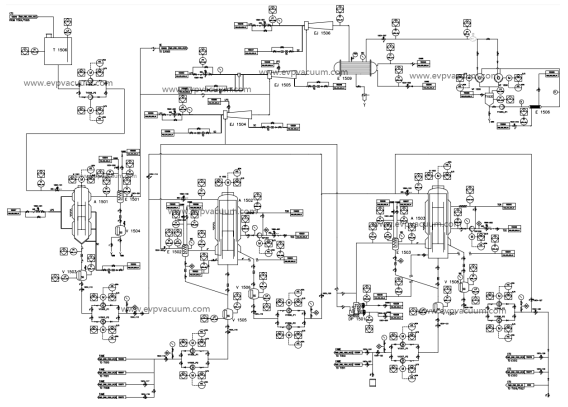

The design drawing of short-path distillation and the on-site photos of the customer’s old unit are provided by EVP to provide a two-stage water ring vacuum pump + roots pump + diffusion pump vacuum unit to improve the vacuum degree and improve the purification performance of the overall short-path distillation process:

Reasonable and efficient vacuum system configuration can not only ensure the normal operation of the short-range steamer (molecular steamer), but also avoid unreasonable investment and save maintenance costs in the later period. Generally speaking, the operation vacuum of the short-range steamer (molecular steamer) is relatively high. Therefore, before entering the short-range steamer (molecular steamer), the vacuum degree of the short-range steamer (molecular steamer) in the material should be generated. The affected light components (non-condensable gas, residual part with low boiling point) are removed first to ensure the normal operation of the short-path steamer (molecular steamer) in a high vacuum state.

Shanghai EVP Vacuum’s vacuum pump unit with short-path distillation is usually used in the following industries:

In the food industry: monoglycerides, palm oil, tocopherol, cod liver oil, squalene, rice bran oil, fatty acids and their derivatives, dienoic acid, industrial vegetable oils, diglycerides, lactic acid, linseed oil, conjugated linoleic acid, etc.Vacuum distillation

In the pharmaceutical industry: acyl amino acids, amino acid esters, vitamin E, glucose derivatives, terpene esters, natural or synthetic vitamins, B-carotene, gingerols, capsaicin, etc. Vacuum distillation

In the chemical industry: | erucamide, alcohol, oleic acid amide, glycerides, herbicides, halogenated alkanes, pesticides, silicone oils, waxes, binary industry | fatty acids, dimer acids, plastics, epoxy resins, epoxy resins carburetor, isocyanate, plasticizer, stabilizer, etc.Vacuum distillation

In the petroleum industry: base oil, bright stock, lubricating oil, petrolatum, fir oil, residual tar, waste lubricating oil industry, etc.Vacuum distillation

In the cosmetic industry: lanolin fatty acids, lanolin, lanolin, alkyl polyglycosides, rose oil, ginger oil, capsanthin, etc. including algae, industrial plant roots, flower capsicum plant extracts, etc.Vacuum distillation

In these industries, the vacuum pump units usually used for short-path distillation include EVP dry screw pump-2-stage Roots unit, EVP steam jet pump + water ring pump – Roots unit, EVP diffusion pump + steam Ejector pump + water ring pump+Roots pump unit, EVP oil vapor pressure pump-steam Ejector pump-water ring pump unit, etc., Shanghai EVP Vacuum Technology Co., Ltd. has been engaged in the vacuum industry more than 24 years, having an experienced and professional technical team. Welcome to consult EVP at any time.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)