Liquid ring vacuum pump used for Wind tunnel experiment platform

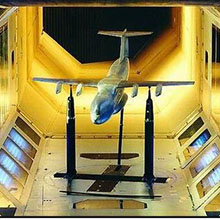

Wind tunnel experiment in fluid mechanics refers to an aerodynamic experiment method in which a model of an aircraft or other object is placed in a wind tunnel to study the flow of gas and its interaction with the model to understand the aerodynamic characteristics of the actual aircraft or other object; In insect chemical ecology, it is an experiment to observe the behavioral response of living insects to odor substances in a rectangular space with circulating air.

The available time for testing a model in a wind tunnel, called the running time, depends on the source of the gas and of the type of exhaust system. Blow-down wind tunnels are characterized by a short running time, whereas the running time for a continuous low wind tunnel is virtually infinite. For a blow-down tunnel, the gas supply can be either the atmosphere or a high-pressure gas storage tank. For the test gas two options of discharge are available, discharge into a vacuum tank or into the atmosphere. In a blow-down wind tunnel, the testing time depends on the capacity of the gas storage tank. If the discharge is into a vacuum tank, the volume of the exhaust tank determines the testing time. Long testing time can be obtained when a compressor or the atmosphere supplies the gas and the exhaust condition is achieved by vacuum pumps.

The corresponding facility is a continuous flow wind tunnel. The limiting factor for a continuous facility is the continuous power supply for driving the compressor. In the case of a supersonic flow wind tunnel with a large test section, the power required can be several hundreds megawatts. For this reason, large test section wind tunnels are usually of the blow-down type, where energy can be stored for a long period and then released for a short time. In the case of continuous flow tunnels, if the gas is supplied to compressor from the atmosphere, the facility operates in an open circuit. A closed-circuit wind tunnel operates with a single machine that is both a vacuum pump and a compressor. In such a case, in order to avoid a continuous rise in gas temperature due to continuous energy release from the compressor, heat must be extracted from the gas by means of a heat exchanger.

To simulate high-altitude rarefied flows, low-density wind tunnels are used. These facilities operate with very small mass flow rates and with large capacity vacuum pumps.Vacuum pump is water-ring vacuum pump, and large flow vacuum pump air capacity of liquid ring vacuum pump from 4500m3/h to 44000m3/h. the vacuum degree reaches 160mbar abs.

EVP 2BE3 liquid ring vacuum pump is single stage pump with simple structure. It’s easy maintenance, reliable,efficient and energy-saving operation . They can run under tough working conditions with large drainage discharge and changing load impact. 2BE3 vacuum pumps adopt unique polytetrafluoroethylene valve plates (former liquid ring pumps use ball valves) for their exhausting systems. Each valve plate is covered on vents in outer side of a port plate and fixed by a stainless steel baffle at its other side. Curvature of the valve plate changes with inlet pressure so that pumping medium can be discharged when it reaches the inlet pressure. Such structure avoids over-compression in a vacuum system and automatically adjusts exhausting area to lower power consumption, thus a best operating efficiency can be obtained.

The key parts of 2BE3 series liquid ring vacuum pumps, such as distribution plate, impeller and pump shaft are simplified in structure with performance improved, thus it’s very energy-saving.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)