Liquid ring vacuum pump used in liquid degassing applications

Background technique:

The liquid contains dissolved gas absorbed from the atmosphere, and the solvent gas in the high-efficiency liquid system will cause inaccurate action of the valve of the infusion pump and disorder of the detection base line. If the content of air bubbles in the liquid is large, the high-precision constant pressure infusion will also be greatly affected. In addition, the dissolved bubbles will also cause errors in the detection results of the refractive index, fluorescence, electrochemistry, and ultraviolet rays. In particular, for precision analysis, when using high-precision flow management analytical precision instruments, when inputting reagents, water or other liquids to the analytical instruments, if the liquid contains air bubbles, the accuracy of the analytical instruments will decrease. Especially if the conveyed liquid is not fully degassed, the infusion pump cannot enter the best working condition.

For juice beverages and other liquids containing fruit and vegetable residues, the fermentation of fruit and vegetable residues and the reaction of the organic matter in the juice with the oxygen dissolved in the juice will affect the taste and storage time of the juice drink, posing a threat to the health of the consumer, and also seriously affecting The economic benefits of fruit juice drinks.

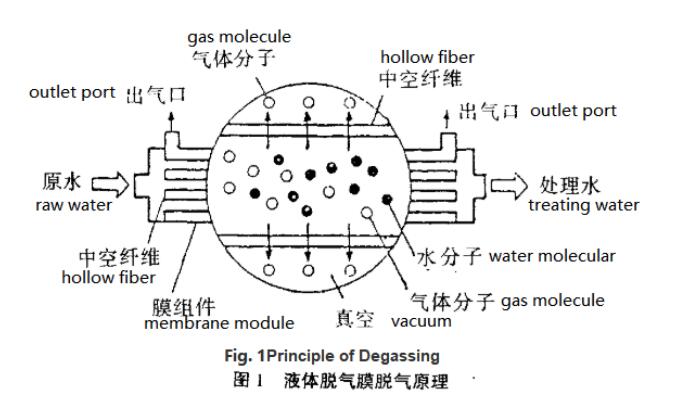

Principle of Degassing:

Membrane filtration and degassing principle The mobile phase online degassing device is usually connected between the solvent tank and the infusion pump and is in an online state. The liquid is sucked from the solvent tank by the infusion pump into the vacuum chamber of the degassing device. The solution passes through the film or film tube set in the vacuum chamber. The film or film tube has high gas permeability to the remaining gas in the liquid. After the solution in the membrane tube enters the vacuum chamber, air bubbles are extracted from the membrane tube under vacuum. The degassed liquid from the outlet of the degassing device is sent to the detector through the infusion pump.

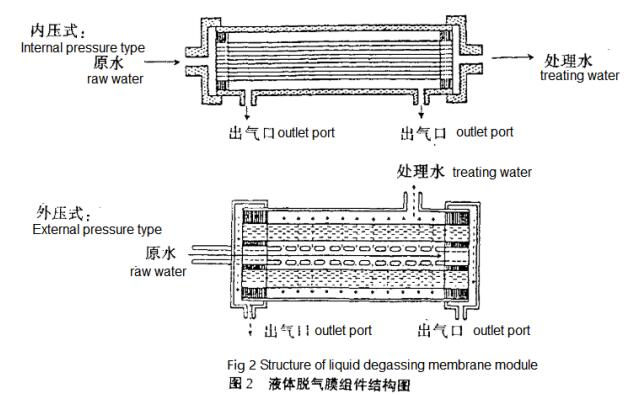

Structure of liquid degassing membrane module:

According to the technical characteristics of the liquid degassing membrane, the degassing effect is closely related to the contact time between the liquid and the membrane surface. The longer the contact time is, the better the degassing effect is. At the same time, the degassing effect is also related to the vacuum degree applied on the membrane surface. The higher and more uniform the vacuum applied on the membrane surface, the better the degassing effect. According to the needs of industrial production, combined with the company’s original product type, we designed two types of degassing membrane module, internal pressure type and external pressure type, to meet the needs of different industries. As shown in Figure 2

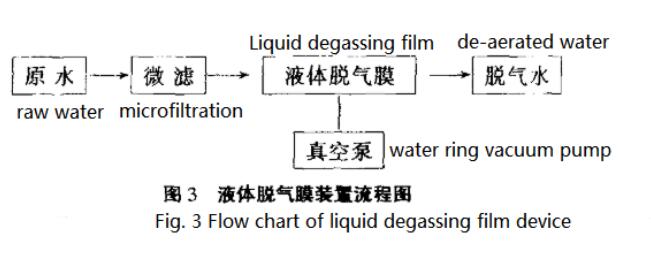

Liquid degassing membrane device:

The liquid degassing membrane device consists of three parts: microfiltration part, degassing part and vacuum part. for detail, pls. see Fig. 3.

1. Microfiltration

The degassing membrane is used to remove impurities and protect the liquid part. The microfiltration part is composed of stainless steel shell, pressure gauge and microporous filter element. The microporous filter core adopts the folding filter element of polypropylene or cellulose acetate material or polypropylene melt blown filter element, and the filtration accuracy is less than 1 μ M.

2.Degassing part

It consists of stainless steel shell, pressure gauge, temperature measuring device and liquid degassing membrane module.

3. Vacuum part

The vacuum part is composed of water ring vacuum pump, vacuum meter, check valve, solenoid valve, etc. its function is to provide vacuum to the vacuum side of the liquid degassing membrane module to form negative pressure, so as to make the dissolved gas in water diffuse outward, so as to achieve the purpose of degassing.

Edited by: Catherine Qin; Copyright: EVP Vacuum Pump

Related products: liquid ring vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)