Liquid ring vacuum pump used in poultry processing vacuum systems

Poultry processing is the application of vacuum in the process of converting live poultry into raw materials suitable for human consumption. This vacuum application continues to grow in the food industry. The reason is that poultry has low fat content and light weight, so it is easy to extract good meat.

EVP vacuum systems installed in poultry processing plants optimize production, are energy-efficient and reliable. Vacuum solutions immediately separate waste products and no longer require employees to handle manually; thus, contributing to safer and more hygienic working conditions. Furthermore, EVP vacuum systems increase production efficiency because employees work alongside the systems and reduce energy by producing little to no pollution.

Reliable Solutions For Poultry Processing

EVP liquid ring vacuum pumps administer vacuum to remove unwanted portions of poultry. Vacuum is applied to processes such as evisceration, vacuum conveying, marinated vacuum pan as well as cookers and fryers to prepare the poultry for packaging and human consumption.

EVP vacuum systems are applied in poultry processing to save energy and provide reliable solutions. Production is optimized in poultry processing with EVP vacuum pumps.

In poultry processing, the product is first eviscerated under vacuum up to 29 in. based on process conditions. Evisceration uses vacuum to remove feathers and internal organs effectively and hygienically without risk of contamination.

Vacuum conveying is a dirty application in poultry processing. Waste products are transferred from one pipeline to another during vacuum conveying. This is a challenging application because high velocity and limited pipe lengths are required. Therefore, EVP creates vacuum to move material safely and efficiently.

Before the poultry is cooked or shipped to the end-user, it is marinated in vacuum pans. During this process, the poultry is marinated under vacuum to open the cellular structure allowing for quicker marination.

The final stage for vacuum during poultry processing is the fryers and cookers. Vacuum is pulled on the fryers or cookers to lower the boiling point of oil or water. This saves energy for cooking the final product.

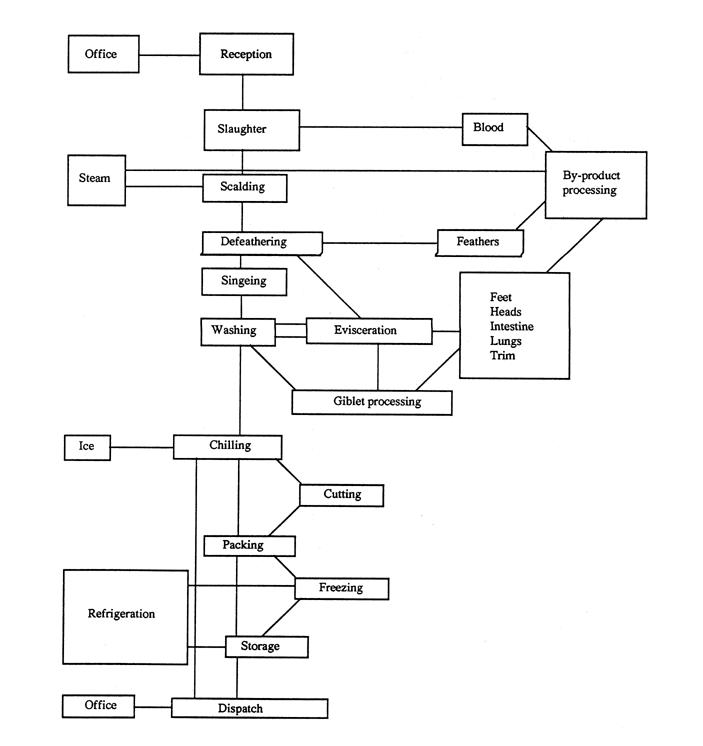

Poultry Processing Flow Diagram

Edited by: Catherine Qin; Copyright: EVP Vacuum Pump

Related products:liquid ring vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)