Vacuum pumps used for palm oil extraction and refining

The oil palm trees grow in tropical regions and they can squeeze the most widely used vegetable oil in the world. Palm oil is stable at high temperatures and can be used for frying and boiling; it can also be mixed well with other oils. The different types of fatty acids in palm oil, as well as their stable properties after refining, make it popular when making packaged fried foods. Its production cost is very low, even lower than cottonseed oil or sunflower oil commonly used for frying. At the same time, palm oil is also a foaming agent in body washes, soaps and disinfectants. Compared with animal fats, palm oil is cheaper and easier to use, so it is also widely used in the cosmetics industry. Palm oil can also be used as a raw material for biofuels, especially in EU countries, where its application is gradually becoming popular. Palm oil can be used to preserve processed foods and to increase the temperature at which ice cream begins to melt. Palm oil can be used as a binder to hold the particles in the fiberboard together. The trunks of oil palm trees also have many uses.

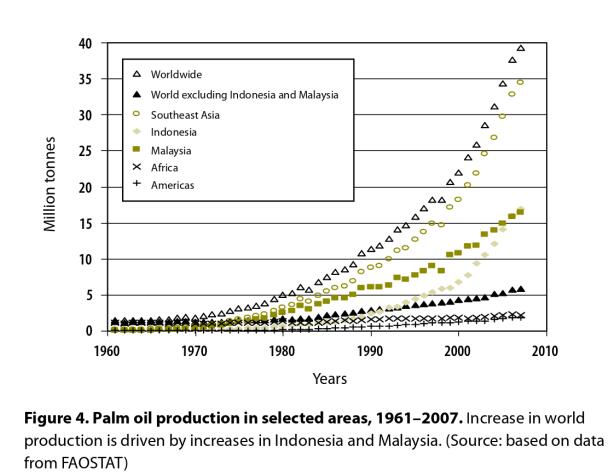

In the past 50 years, palm oil production worldwide has risen steadily. From 1995 to 2015, production quadrupled, from 15.2 million tons to 62.6 million tons. By 2050, this number will quadruple, reaching 240 million tons. The “footprint” of palm oil production is amazing. 10% of the world’s land used to grow crops for many years is palm. Currently, 3 billion people in 150 countries use palm oil-containing products. Globally, the average annual consumption of palm oil per capita is 8 kg.

Adsorption decolorization refers to the use of adsorbents to remove the pigment components in the oil. The pigment composition in edible oil is complex, mainly including chlorophyll, carotene, flavonoid pigment, anthocyanin, etc. The decolorization process is usually carried out in hot oil. The action of adsorbent and pigment is accompanied by oxidation reaction, which affects the color and stability of the finished oil, so it needs to be carried out under vacuum conditions. The vacuum pump can be used in the evaporation, distillation, extraction, degassing, drying, filtration and other steps.

There are many different processes and project scales for a palm oil mill. The products in which EVP caters to for palm oil mill projects will vary accordingly.

Liquid ring vacuum pump in palm oil mill:

Our DLV two stage liquid ring vacuum pump are well used in palm oil mill, the material we suggest is SS316L.

1.Wider range of suction pressure. Compared to other double stage pumps (suction pressure 50mbar-150mbarA), DLV pump works in 25mbar~1013mbar pressure, with less energy consumption, with15%-20% lower than traditional ones.

2. All kinds of models to fulfill various process requirements.

3. Materials are optional to make the pump possible to work in various harsh environment, Such as carbon steel, stainless steel, dual-phase steel, titanium, etc .

4. Single or double mechanical seal and several flush method.

5. Precise casting, high standard accessories, imported bearing; high efficiency and energy saving.

Dry Screw Pumps

Screw pump is the best choice for fuel pump, diesel pump, heavy oil delivery pump, lubricating oil pump, lubricating oil pump or chemical pump.

Screw pump can transport a variety of non-solid containing fluid medium or very high viscosity medium. They have a wide range of availability and high reliability, suitable for lubricated or non-lubricated media, corrosive media or gas-liquid mixtures.

Capacity: 0.5-1500m3 / h

Pressure: 0.1-2.0 Mpa

Viscosity: 0.5-100,00mm2 / s

Temperature: -30-200 ℃

Media: various lubricants and fuels

Structure: horizontal, vertical, portable structure, heating chamber

Safety: explosion proof, waterproof, safety valve, alarm sensor.

Edited by: Annie Hou / Shanghai EVP Vacuum Technology Co., Ltd

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)