Water pump in central negative pressure application in stomatology department of hospital

(1)Central suction system assembly:

Water ring vacuum pump vacuum suction system consists of water ring vacuum pump, dirt filter, gas-water separator, solenoid valve, check valve, negative pressure unloading valve, negative pressure gauge, piping, control box and other components. Installation of the system components as follows: negative pressure unloading valve, negative pressure gauge and check valve installed on the suction pipe of water ring pump, Dirt filters install at the import of the check valve. Then connect the dirt filter to pipe of office by hose, and make the gas-water separator is fixed on the wall (the height about 1 m). Making the gas-water separator connected to exhaust pipe of water ring vacuum pump by hose. The solenoid valve be installed at the water inlet port of water ring pump, and then connect to the water source. Finally, the power line of motor and solenoid valve and signal line of system be connected to the the control box.

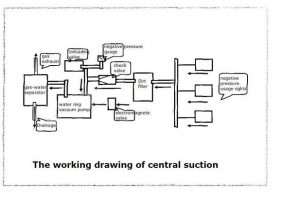

(2) The working process of the Central suction system:

The working process drawing of central suction system as follow, Once the electrical signal arrived to the electrical control box, electric control box immediately supply power to the water ring vacuum pump and solenoid valve and make them work, the tap water through the electromagnetic valve into the water ring vacuum pump at same time, so that the whole system will produce negative pressure. The mixed liquid with a little particles and splash during treatment be sucked into the pipe, it through the dirt filter, check valve and the suction tube into the pump body with the air, then it arrived to gas-water separator through the exhaust pipe, The gas be exhausted by the air outlet and at the same time the liquid be drained by water outlet under the gas-water separator working.

(3)The efficacy of the water ring pump system at stomatology department:

Compared with imported products, At present, most of dental hospitals’ oral cavity suction system is imported products, such as the United States M idm arkCV series, Italy Cattani Turbo. sm art series and the German DUrr V S series and so on. The performance and quality of these imported products are be trusted worthy, but the price and maintenance costs are very high. Using the 2BV2 070 water ring vacuum pump technical data compared with imported products as follow:

(4)The pipes installation requirements of Central suction system:

Central suction system’s pipe inside should be smooth and can bear some pressure, such as PV C-U tube that the daily be used pipe of tap water supply. Pipe fittings should choose 45. Angle of the accessories, such as 45. Angle elbow, trigeminal, etc., in order to minimize the resistance of the air flow in the pipe. The supervisor should choose the pipe of the same specification as the suction pipe of the water ring vacuum pump, the diameter of the branch pipe should be selected a smaller tube than the competent one, terminating a tube with an optional DN 25 or tubing matching the diameter of the negative pressure adapter. Pay attention to the pipes laying some slope, vertical pipe can not be vertical alignment of the water ring vacuum pump suction pipe, it’s best way that pipe should be lay a horizontal section after down, and then connect to the dirt filters of system.

(5)The maintenance of Central vacuum suction system:

The maintenance of Water ring vacuum pump Central vacuum suction system should pay attention to the following points.

① Water ring vacuum pump power supply is 380 V or customization according to the customer, it can’t without phase when it’s working. so routine maintenance should pay attention to the contact loss of the main contactor, it should be replace the contactor immediately if it has serious loss;

② Regular cleaning the filter screen, and the mesh diameter of the filter screen should be less than or equal to 0.5 nqlTl, because the solid particles that diameter more than 0.5 mm will damage the impeller;

③ pump body can’t lack water, it will cause the pump body heat then damaging the impeller and other components if it lack of water;

④ pay attention to check the bearing working situation, because the bearing life is short. Usually the bearings can be used up to 2 years. If it be founded to have a larger noise, shaft seal leakage or mechanical vibration etc., it is necessary to check the bearing and shaft seal whether damaged, it should be replace immediately once it’s damaged;

⑤ Regular cleaning the filters and pipes.

Tags : vacuum pump, Liquid ring pump, vacuum system

Edited by Jinny Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)