Vacuum Unit in Pharmaceutical Equipment

Vacuum units are often used in pharmaceutical processes for vacuum distillation, vacuum crystallization or vacuum drying processes to treat pharmaceutical materials. When the drug materials are relatively viscous (such as paste materials, or when the amount of liquid materials is small), these materials have the common feature of removing the liquid materials mixed in the drug materials, which requires very low pressure, generally in the hundreds of Pascals, dozens of hundred Pascals, or even hundreds of Pascals, can remove these relatively difficult to evaporate liquid materials.

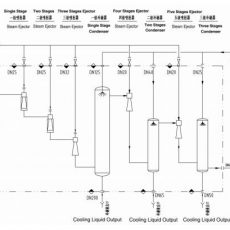

The processes of vacuum evaporation, concentration, distillation, crystallization, drying, extraction, sublimation, vacuum mixing, vacuum reaction, absorption, vacuum filtration and conveying materials in the chemical and pharmaceutical industry are all completed by means of vacuum equipment, and vacuum pumps (sometimes units) are usually water ring, rotary vane vacuum pump rotary piston vacuum pumps. The following is a brief description of the main processes of the Shanghai EVP Vacuum Technology in the pharmaceutical industry: drying, distillation, and degassing.

Vacuum drying:

Drying is a relatively low cost, relatively low temperature process in the pharmaceutical process that evaporates liquid from solids by reducing the degree of vacuum, thereby degrading/oxidizing the biological or active ingredients without damage. After drying, the remaining portion is a granular preparation, which is compressed into tablets, and the remaining wet level is low, which can prolong the storage period of the product.

Vacuum distillation:

The distillation column provides a gas pressure separating the different liquid components through a vacuum system, and two or more substances having different temperatures, pressures, compositions, and phase states are separated by changing the degree of vacuum and temperature.

Degassing:

Degassing is the removal of gases that dissolve or remain in the liquid or product. The use of a vacuum system removes gases from the liquid, improves its physical properties, improves product quality for further processing, and avoids cross-contamination or corrosion.

Keywords: vacuum pump unit; liquid ring vacuum pump; rotary vane vacuum pump; rotary piston vacuum pump

Edited by: Emily Fu / Shanghai EVP Vacuum Technology Co., Ltd.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)