Dry screw vacuum pump used in penicillin crystallization process

Introduction

Penicillin is a kind of antibiotics. It is a medicine extracted from penicillium culture solution. It is the first antibiotic that can treat human diseases.

Chloramphenicol has a broad-spectrum antibacterial effect. It has a stronger effect on gram-negative bacteria than gram-positive bacteria. It has a stronger effect on typhoid, influenza and bacillus pertussis than other antibiotics. It has a stronger effect on rickettsiae infections (such as typhus). ) And viral infections (such as trachoma) have a good effect. It also has a strong antibacterial effect on Brucella, Escherichia coli, Aerobacter, Pneumoniae, Shigella, Vibrio cholerae, Meningococcus, Neisseria gonorrhoeae, etc. This product is a bacteriostatic agent. Its mechanism of action mainly inhibits the synthesis of bacterial protein. It acts on the 50S subunit of ribonucleoprotein body to inhibit the action of peptidyl transferase and prevent the growth of peptide chains. Clinically, it is mainly used for typhoid fever, paratyphoid fever and other Salmonella infections, with good curative effect, and it is still the first choice for the treatment of these diseases. In addition, it also has a good effect on meningitis and other infections caused by meningococcus, pneumococcus, influenza bacillus, streptococcus, etc. It can also be used for whooping cough, brucellosis, rickettsial disease, etc.

1 The production process of penicillin

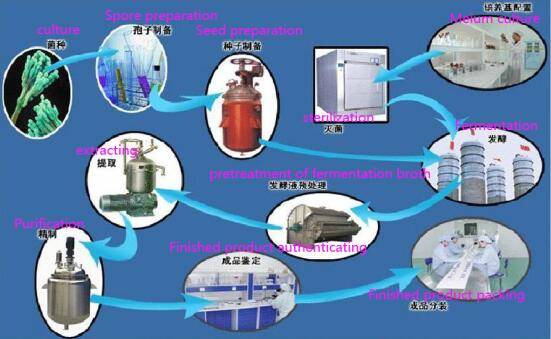

Generally speaking, there are four links in the production process of penicillin. The first step is to process the raw materials into a first-class seed tank by means of medium preparation and steam sterilization. At the same time, the rice spores in the slant mother bottle of penicillin should be added into the primary seed tank after corresponding treatment. The second step is to use the medium preparation and steam sterilization to cultivate the raw materials into a secondary seed tank. The third step is to add the treatment of fermentation tank on the basis of the second step to form fermentation liquid. The last step is to put the obtained fermentation broth in the belt release tank to obtain the final fermentation broth and complete the fermentation preparation of penicillin

2 The specific production process of penicillin

2.1 Fermentation process

As the production of penicillin is mainly by fermentation process, it is very important to ensure the fermentation process. In this operation, it is necessary to strictly control the preparation of spores, seed tank and fermentation tank culture, and standardize the process operation method. First of all, in the preparation of spores, the spores stored in sand should be taken out and put into the medium made of glycerol, glucose and protein. In this environment, the spores can be divided, subcultured and activated by slant culture. In the process of culture, the temperature should be controlled at about 26 ℃, which is the most suitable temperature for spore passage and activation. Generally, the culture time is about 7 days. After the single colony is obtained, it can be cultured in the same way for 7 days, and then the obtained slant spores can be transplanted into the solid medium, which can be composed of rice or millet. The final spores should be obtained by continuous culture for 7 days on solid medium. After shake flask test, the obtained spores can be used in the next stage of production only after their potency and miscellaneous bacteria meet the relevant regulations. Secondly, in the preparation process of seed tank and fermentation tank, in order to make the produced seeds have strong mycelium, enough energy should be given, Therefore, a certain carbon source or organic nitrogen source can be added into the medium of the seed pot. In addition, the fermentation of penicillin generally needs to be divided into three levels, and the fermentation quality of each level will affect the preparation quality of penicillin, so it is necessary to strictly control the preparation conditions of fermentation tank.

2.2 Sterilization of the culture medium

Penicillin is a kind of fermentation production, so it requires high sterilization of medium. Therefore, it is also very important to strengthen the control of the sterilization of the medium. Generally, the sterilization of penicillin medium is mainly by continuous sterilization and real tank sterilization, which means that after the medium is prepared, it is directly driven into the continuous sterilization tower, and then the bacteria in the medium are killed by high temperature steam. After sterilization, it was put into the maintenance tank for 5min and then transferred to the cooler, and then the cooled medium was used in fermentation. This sterilization method is more thorough, can complete the sterilization work at once, and will not cause too much damage to the nutritional components. The sterilization of real tank is a common technique in the sterilization of penicillin medium. The main working process is to directly enter the culture medium into the fermentation tank, then heat the fermentation tank, and stop heating after the temperature reaches 121 ℃, and keep it for half an hour to complete the sterilization. After sterilization, the sterile air is put into the fermentation tank, and cooled to the appropriate temperature of inoculation, and ready to move seeds。

Process flow chart of penicillin production

3 The main process indicators that affect the quality of penicillin production

Temperature control

PH value control

Control of dissolved oxygen

Control of mycelial growth rate, form and concentration

Defoaming

Sampling

Comparison of advantages during the test:

①During the crystallization process, the vacuum degree of dry screw vacuum pump is far better than that of water ring vacuum pump.

②Dry screw vacuum pump distillate temperature is easy to control, more stable than water ring vacuum pump.

③The amount of distilled liquid within 1 hour after crystallization, the dry vacuum pump is 400-500 liters more than the water ring vacuum pump.

④Compared with water ring vacuum pumps, dry screw vacuum pumps shorten the running time of each batch by 30-40 minutes, which is more energy-saving.

⑤Use a dry screw vacuum pump to recover about 2.5 liters of butanol water per batch, of which 4/5 water is 1/5 butanol, that is, about 0.5 liters of butanol can be recovered per batch.

⑥The cooling water uses circulating water, the consumption is significantly lower than that of the water ring vacuum pump, and there is no water pollution.

In addition to its own environmental protection and energy saving, by increasing the degree of vacuum, the reaction and distillation temperature is reduced, the reaction and distillation time are shortened, and the purity is improved! Especially in the recovery of lysozyme of the raw material drug, the quality of the drug is improved and the lysozyme is realized Recycling of the pumps will help customers create value tangibly!

Dry screw vacuum pump, Roots screw unit, screw with lysozyme recovery and screw Roots unit:

◆ Solve the problems of liquid phase entering the pump, liquefaction, crystallization and coking in the pump cavity.

◆ The screw pump made of corrosion-resistant materials solves the problem of chemical corrosion.

◆ Innovative sealing method to completely solve the sealing problem.

Copyright: EVP Vacuum Solutions