Brand: EVP

Classification: Vacuum Pump

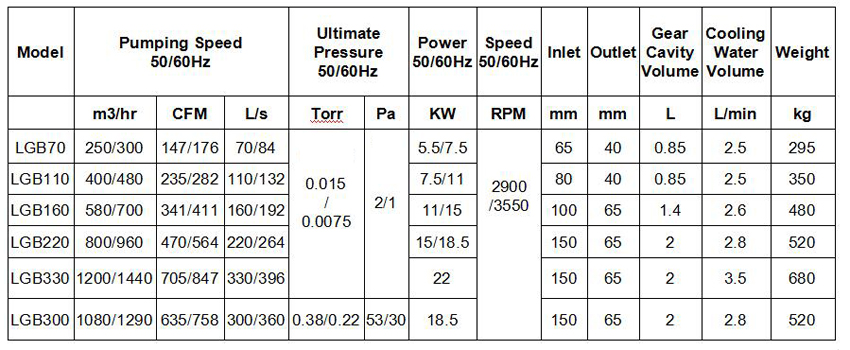

SUCTION CAPACITY:250M3/H TO 1440M3/H

VACUUM RANGE:0.02MBAR ABS

Availability : In Stock

LGB Series screw vacuum pump is "NO OIL NO WATER" in contact with the process vapors,so they also called dry screw vacuum pump.

Technical Specification:

Remark:

1) The oil consumption on above sheet is for reference only. The machine can always adopt fluoride or mineral substance oil. Pump oil and lubricant oil will be matched before delivery.

2) Above cooling water consumption data is tested with ambient temperature at 30℃, cooling water suction temperature at 20℃,and water pressure from 0.15MPa to 0.2MPa. Various working condition will cause different cooling water consumption.

LGB series dry screw vacuum pumps can manage both condensable vapors and some solids with no residue. They offer a number of advantages over the traditional vacuum pump designs. There’s is “NO OIL NO WATER” in contact with the process vapors, so therefore they are considered environmentally friendly.

Applications :

Chemical & Pharmaceutical Processing,Solvent Recovery, Crystallization, Vapor Coating,Petroleum and semiconductor markets.etc.

Characteristic :

1. Oil& Water free Dry running operation makes clean vacuum.

2. Can achieve ultimate vacuum as low as 0.6Pa

3.Quiet operation; Equipped with special silencer,lower noise.

4.No metal-metal contact between Screw and Casing ensures long pump life.

5.Simple design results easy maintenance.

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.