Vacuum mud refining machine water ring vacuum pump

Vacuum mud refining is an important part in special ceramic industry. After vacuum treat and vacuum degassing, mud get better plasticity and larger density. Porcelain product formed with such mud has a high strength and less deformation. Therefore, vacuum mud refining machine vacuum pump directly influence to porcelain product quality.

Traditional mud refining machine with normal vacuum pumps

Special ceramic factories are currently choosing oil vacuum pumps like rotary piston vacuum pump, rotary vane vacuum pump, reciprocating vacuum pumps etc according to a marketing investigation. There are a lot of disadvantages in operation because of product design. Taking piston vacuum pump as a example, we make a simple list of disadvantages:

Poor environmental performance

As we all know, the rotary piston vacuum pump is a oil-sealed and mechanical vacuum pump. It has larger oil consumption because it needs vacuum oil to seal and lubricate, for example, fuel injection at 40-50L for H-150 Model. With sealing and mechanical parts perishing in some years, oil leak is inevitable and production site smears stained. If vacuum oil lubricates not well, a “ burning oil” phenomenon is brought up due to eccentric wheel and cylinder mechanical friction, and then work site is filled with fumes which is not good for worker’s health.

Mud pollution risk

When the operation to stop rotary piston vacuum pump is not done well, vacuum oil will return to mud refining machine, which causes mud pollution. Mud must be scrapped and there is economic loss.

High maintenance cost

Rotary piston vacuum pumps are mechanical. It is absolute to lubricate internal parts with vacuum oil due to friction and wear, so maintenance cost will be very high. Once rear cylinder wears, repair work is quite difficult.

It is a taboo that water comes into vacuum oil because the moisture causes vacuum oil emulsion to impact oil performance. Lubricating oil in vacuum pump is tend to be polluted due to the water in mud refining gas. It is necessary to add lubricating oil every day even to replace. Therefore running cost is very high.

Poor efficiency

Water gasification comes up easily because of high temperature in summer. It causes that the vacuum in oil ring vacuum pump is often not enough. Some factories have to install air conditioner or heat pumping pan just to solve such problem. Here are greater energy waste and another expense.

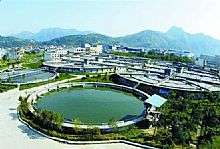

Mud refining machines equipped with water ring vacuum pump

Compared with oil vacuum pump, our water ring vacuum pump designed for mud refining machine has a lot of advantages such as a simple structure, reliable operation, oil free, energy saving and high efficiency. It is innovative application in ceramic and porcelain industry, and more and more factories tend to use.

A simple structure and a long service life

Water ring vacuum pump is sealed with water. When impellers rotate, there is centrifugal force. Water is driven away and a space between impeller and pump container is formed. Water ring vacuum pump suck and exhaust air with the space periodical change. There is no contact between the impeller and the pump body and no mechanical friction. Service life is quite longer.

Environment protection and non-refueling

Water ring vacuum pump takes water as working fluid. There is no internal friction and no need to adding lubricating oil and vacuum oil, so no oil contamination to work site and mud.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)