Vacuum concentration technology

Vacuum concentration advantages:

Liquid substances in the solvent evaporated under boiling state quickly, its boiling point due to the pressure change, the pressure increases, the boiling point rises, the pressure, the boiling point is lowered. E.g. milk 101kPa at a boiling point of 100 ℃, while under a vacuum of 82.7 ~ 90.6KPa, the boiling point of only 45 ~ 55 ℃. Since at lower temperatures and evaporated. Also, because the material is not high temperatures, avoiding the destruction and loss of heat-labile components, and better preservation of nutrients and aroma materials. In particular, some amino acids, flavonoids, phenols, vitamins and other substances, and prevent heat damage. Some carbohydrates, protein, pectin, phlegmatic and other viscous materials, low-temperature coking material to prevent evaporation.

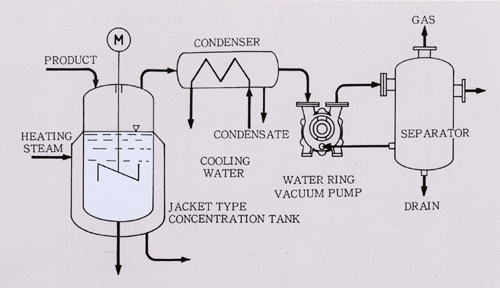

Flow chart of a vacuum concentration plant

Which type of vacuum pumps can be widely used in vacuum concentration technology?

Steam Ejectors

Reciprocating vacuum pumps

Liquid ring vacuum pumps

Dry vacuum pumps

As a professional China vacuum pumps manufacturer,we can provide our solutions to you as well as help you select suitable vacuum pumps in your technology process with our over decades years experience.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)