Roots blower used in sewage treatment application and roots blower maintenance

roots blower Introduction

Roots blower is the basic equipment for blowing oxygen in the process of biochemical reaction in sewage treatment plant. The equipment is suitable for the application of urban sewage treatment process of various scales, and is also suitable for the blast aeration of the biochemical reaction process of small city sewage treatment plants. This article details the principles, usage and basic maintenance methods of Roots blowers in sewage water treatment.

In the biological contact oxidation treatment, the dissolved oxygen consumed by aerobic microorganisms in the oxidation and decomposition of organic matters, so it is necessary to supplement the dissolved oxygen to the sewage in time. Using microporous aerator, the roots blower with oxygen transfer rate of 25-28 belongs to volume rotary blower, which is the basic equipment of aeration in the biochemical reaction process of sewage treatment plant. The biggest feature is that when the pressure is adjusted in the allowed range, the flow rate changes little, and the pressure selection range is very wide, which has the characteristics of forced gas transmission. The medium does not contain oil during transportation. The utility model has the advantages of simple structure, convenient maintenance, long service life and small vibration of the whole machine. The transmission medium of Roots blower is clean air, clean medium oil, sulfur dioxide and other gases. In view of the above characteristics, it can be widely used in the air sand settling process of various scale urban sewage treatment plants and the air blast aeration of biochemical reaction process of small urban sewage treatment plants.

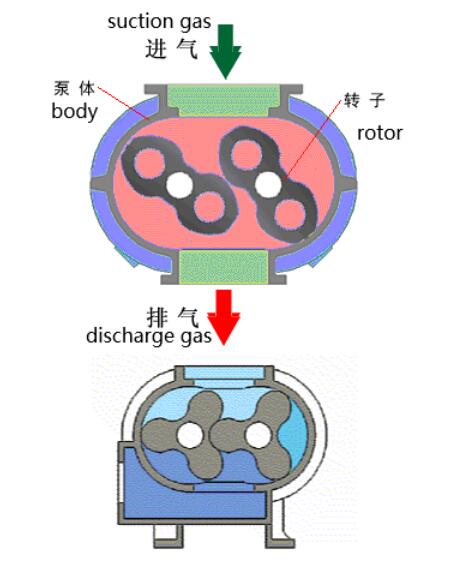

roots blower working principle:

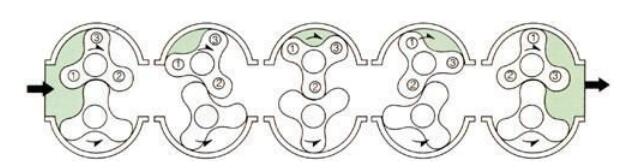

The Roots blower is a positive displacement blower. The air volume delivered is proportional to the number of revolutions du. The three-blade impeller is sucked and exhausted three times by two impellers per rotation. Compared with the two-blade type, the gas pulsation is reduced and the load is reduced. The change is small, the mechanical strength is high, the noise is low, and the vibration is also small. There are two three-bladed impellers on the two parallel shafts. There is always a small gap between the wheel and the inner hole surface of the elliptical chassis and each of the impellers. Because the impellers rotate in opposite directions at a constant speed, the box body A certain amount of gas surrounded by the impeller is transported from the suction side to the discharge side. Each impeller is always maintained in the correct phase by the synchronous gear, and there will be no contact with each other, so it can be speeded up, does not require internal lubrication, and has a simple structure, smooth operation, stable performance, adaptable to multiple uses, and has been used in a wide range of field.

Schematic diagram of the working principle of Roots blower

Diagram of working principle of roots blower with three lobes

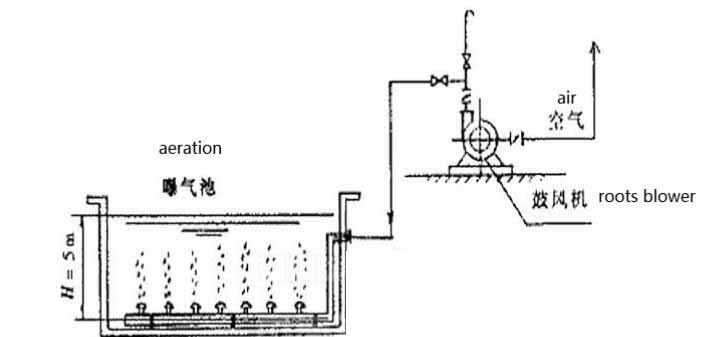

Roots blower in sewage treatment industry

Roots blowers are used in sewage treatment plants to oxygenate biochemical reactions. When selecting a fan, the wind pressure depends on the water depth, pipeline resistance and water viscosity, and the air volume depends on the volume of water.For small sewage treatment equipment, the boost pressure of the Roots blower is generally 34.3-39.2kPa, and the flow rate is less than 10m’/min . But now there are also larger fans for sewage treatment, the flow rate reaches 60m/min.

Roots blower in sewage treatment precautions

The Roots blower acts as the main structure for biological treatment of sewage in the aeration work of water treatment. In order to maintain the life activities of microorganisms in the work process, it is necessary to ensure that there is a certain amount of dissolved oxygen in the water. Aeration is to continuously blow the air into the water, or to dissolve the oxygen in the air into the water. The aeration tank is generally made of reinforced concrete, mainly by means of Roots blower aeration and mechanical aeration. The main method of blower aeration is also called compressed air aeration, Roots blower vortex fan, water ring fan, centrifugal fan, rotary fan, etc. can be used as its main aeration equipment.

When the equipment is tested before the ventilation, the Roots blower should pay attention to the ventilation test before the water is vented.Start the fan before ventilating, turn on 50% of the air volume, and send it to the aeration pipeline of the biochemical pool for detection.Check that the pipeline cannot be leaked. When the phenomenon occurs, special attention should be paid to the operation of the fan. During the leak test, an appropriate amount of lubricating oil should be continuously added to the tuyere to ensure the normal operation of the equipment to avoid no-load operation.The lubricating oil cannot be automatically recycled when there is no pressure to avoid the appearance of equipment The situation of lack of oil operation.

Causes of motor overload of Roots blower

1.Compared with the specified pressure, the pressure difference is large, i.e. the back pressure or inlet pressure is high

2.Compared with the flow required by the equipment, the fan flow is too large, so the pressure increases

3.The inlet filter is blocked, and the outlet pipe is blocked or blocked 4. The rotating parts collide and rub (get stuck)

4.Collision and friction of rotating parts (stuck)

5.The oil level is too high;

6.The narrow V-belt is overheated, the vibration is too large, and the pulley is too small.

Solutions for overload of Roots blower motor:

1.Reduce the pressure to the specified value;

2.Put excess gas into the atmosphere or reduce the blower speed;

3.Remove obstacles;

4.Stop the machine immediately and check the cause;

5. Adjust the oil level to the correct position; 6. Check the belt tension and replace it with a large diameter pulley.

Noise treatment of Roots blower

1. If the belt slips and becomes loose, adjust the tightness or replace it.

2. The lubrication of gear or bearing is not enough. After the machine is shut down, add oil or gear grease.

3. Foreign matters inside the fan or collision of fan impeller, check the inside of the fan after closing.

4. The outlet of the fan or take care of the leakage, check the cause of the leakage after the shutdown and screw it down again.

5. Check valve or pressure relief valve for failure, check the cause of failure, repair or replace.

6. If the pressure rises abnormally, check the pressure gauge and working conditions, and eliminate the causes of the pressure rise abnormally. 7. If the connecting bolts are loose, check the specific loose bolts and tighten them!

Edited by: Catherine Qin;

Copyright: EVP Vacuum Pump

Related products: roots blower

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)