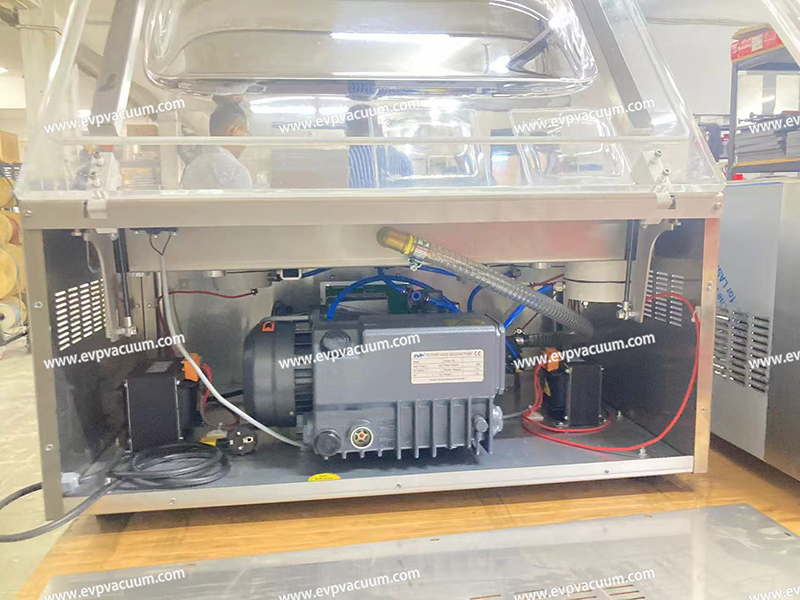

Rotary vane vacuum pumps for electronic device packaging

Rotary vane vacuum pumps are commonly used in electronic device packaging to create a controlled environment by removing air and other gases. They play a crucial role in processes like hermetic sealing, MEMS packaging, and LED encapsulation, where moisture and oxygen must be minimized to ensure device reliability.

Key Applications in Electronic Device Packaging

Hermetic Sealing

Prevents moisture and gas ingress in sensitive components (e.g., ICs, sensors).

Extends device lifespan by reducing oxidation.

MEMS & Semiconductor Packaging

Ensures clean, low-pressure environments for delicate microstructures.

Used in wafer-level packaging and vacuum molding.

LED & OLED Manufacturing

Removes contaminants before encapsulation to prevent dark spots and degradation.

Vacuum Casting & Encapsulation

Eliminates air bubbles in epoxy resins for better thermal and mechanical stability.

Advantages of Rotary vane vacuum pumps

High Vacuum Levels (~0.1 to 1 mbar) – Suitable for most packaging needs.

Reliable & Durable – Oil-lubricated versions offer long service life.

Compact & Low Vibration – Ideal for cleanroom and precision applications.

Cost-Effective – Lower initial cost compared to turbomolecular or dry pumps.

Considerations for Selection

Oil vs. Dry Pumps:

Oil-lubricated: Better ultimate vacuum but risk of backstreaming.

Dry (oil-free): Cleaner but may have lower vacuum levels.

Maintenance: Regular oil changes (for oil-lubricated) and filter replacements needed.

Contamination Control: Use traps or filters if oil vapor is a concern.

Alternative Vacuum Technologies

Diaphragm Pumps – Oil-free, but lower vacuum.

Scroll Pumps – Clean, medium vacuum, low maintenance.

Turbomolecular Pumps – For ultra-high vacuum (UHV) in advanced semiconductor packaging.

Conclusion

Rotary vane vacuum pumps are a reliable and economical choice for electronic packaging where moderate vacuum is sufficient. For oil-sensitive applications, consider dry pumps or hybrid systems to avoid contamination.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)