Stainless steel rotary vane vacuum pump

Stainless steel rotary vane vacuum pump product introduction:

Rotary vane vacuum pump is divided into two types: 2XZ rotary vane vacuum pump and 2X rotary vane vacuum pump. Its working performance consists of two parts: high-pressure stage and low-pressure stage. The suction port of rotary vane vacuum pump is connected with vacuum equipment, and the gas in the container is sucked and discharged in large quantities during operation. When the equipment obtains vacuum, the high-pressure exhaust valve sheet will be closed, and the gas inhaled by the high-pressure stage will be transported to the second stage, and a certain vacuum can be obtained by the second stage inhalation and exhaust vacuum equipment. The technical parameters of the vacuum pump are 6X10-2. Pump and motor shaft, high speed, small shape, compact structure, easy to work, especially the use of metal scraper, suitable for diffusion pump front pump, precision instrument matching and use, used in medicine, food packaging, electronics and other units.

Stainless steel rotary vane vacuum pump supply

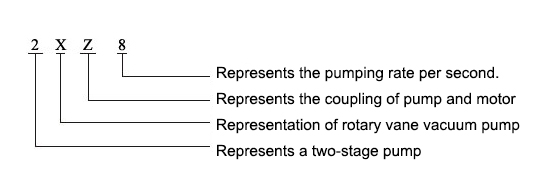

Type Significance of Stainless Steel Rotary Vacuum Pump:

Performance parameters of stainless steel rotary vane vacuum pump:

|

Model

|

2XZ-0.5

|

2XZ-1

|

2XZ-2

|

2XZ-4

|

2XZ-8

|

2XZ-15

|

|

Pumping rate(L/S)

|

0.5

|

1

|

2

|

4

|

8

|

15

|

|

Extreme pressure(Pa)

|

6.0×10-2

|

6.0×10-2

|

6.0×10-2

|

6.0×10-2

|

6.0×10-2

|

6.0×10-2

|

|

speed(rpm)

|

1440

|

1440

|

1440

|

1440

|

1410

|

1420

|

|

Motor power(kw)

|

0.18

|

0.25

|

0.37

|

0.55

|

1.1

|

2.2

|

|

Suction caliber(mm)

|

16

|

16

|

25

|

25

|

40

|

40

|

Application and scope of stainless steel rotary vane vacuum pump

1. Vacuum pump is one of the basic equipment used to extract gas from sealed container. It can act independently, and can also be used as the front pump of booster pump, diffusion pump, molecular pump, etc. to maintain the pump and the pre-pump of titanium pump. It can be used in the manufacture of electric vacuum devices, thermos bottles, vacuum welding, printing, plastic absorption, refrigeration equipment repair and instrument matching. Because of its small size, light weight and low operating noise, it is more suitable for laboratory use.

2. Vacuum pump is allowed to run continuously for a long time in the ambient temperature range of 540 and the inlet pressure is less than 1.3X103Pa. When the relative humidity of the extracted gas is greater than 90, the air ballast valve should be opened.

3. The intake port shall not operate more than one minute continuously and smoothly.

4. Vacuum pumps are not suitable for extracting gases that corrode metals, react chemically with pump oil, contain particulate dust, and contain excessive oxygen, sexual and toxic gases.