Vacuum Gate Valve Selection Guide

Vacuum gate valve selecting for precautions:

1. Scope of work pressure: Determine the maximum and minimum required work pressure based on the actual application scenario.

2. Temperature adaptability: Consider the impact of the working temperature of the medium and the ambient temperature on the valve.

3. Connection method: Common types include flange connection, threaded connection, etc., and the appropriate type should be selected according to the site conditions.

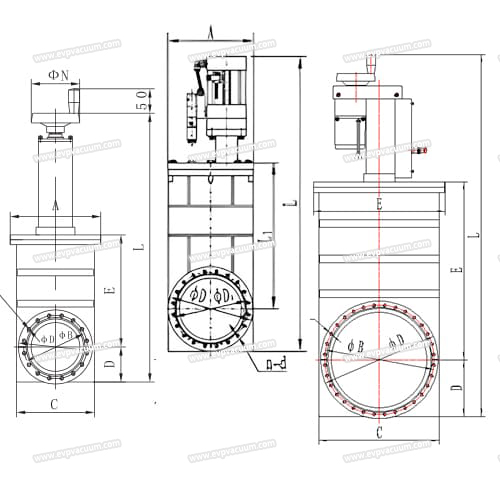

4. Drive mode: Choose electric, pneumatic or manual operation according to the requirements of automation level.

5. Size specifications: Determine the specific model of the valve based on the diameter of the pipeline.

6. Brand reputation: Choosing a brand not only means more reliable product quality, but also allows for more comprehensive after-sales service.

7. Price factor: On the premise of meeting performance requirements, compare the prices of different manufacturers and choose products with high cost-effectiveness.

8. Technical support: Some suppliers may provide technical support and consulting services, which are very important for first-time users.

Vacuum gate valve is a valve specifically designed for use in vacuum systems, whose main function is to control the flow of gas or liquid in a vacuum environment. The basic working principle is to adjust the flow rate by driving the plug board up and down through an electric device or manual operation, thereby changing the cross-sectional area of the flow channel. When the plug board is raised, the valve is fully open, allowing fluid to pass smoothly; When the plug plate descends into contact with the valve seat, the valve closes, preventing fluid flow.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)