Vacuum Pumps applied to Vacuum Wood Grain Transfer Printing Machine

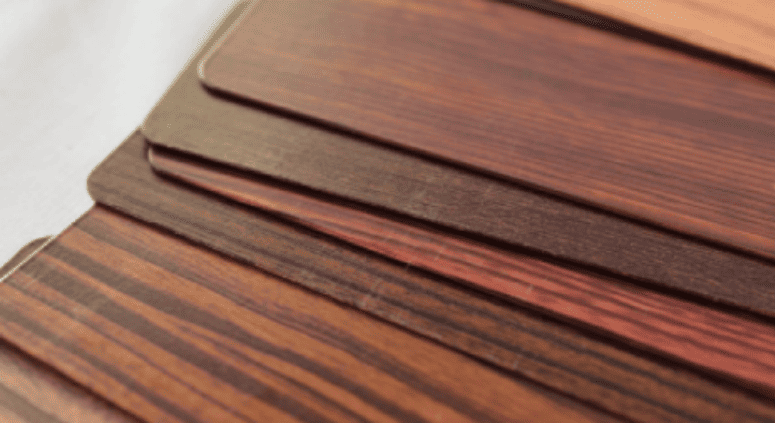

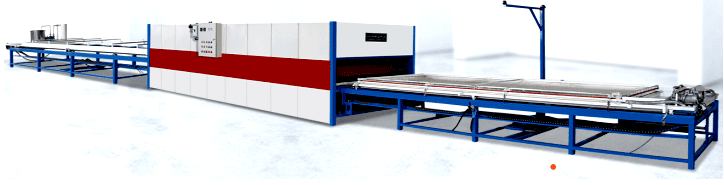

The transfer printing technology is an emerging technology. It refers to the use of transfer paper as a transfer carrier for printing, and the use of vacuum to create negative pressure, so that the transfer paper and the transfer product are fully in contact and bear a certain pressure, and the transfer of printing is completed at a suitable temperature. It is specifically classified into cover film type or bag type vacuum transfer, which is used in different industries. Vacuum wood grain transfer printing machine is a product launched for wood grain transfer on the surface of steel and wooden doors. The product is high quality, low price, easy to operate, and popular with users. The vacuum wood grain transfer machine makes full use of the cover film to transfer to the product under the vacuum of the EVP vacuum pump. According to the working principle of thermal sublimation, the image is formed in one time, without color matching, and a clear pattern is printed.

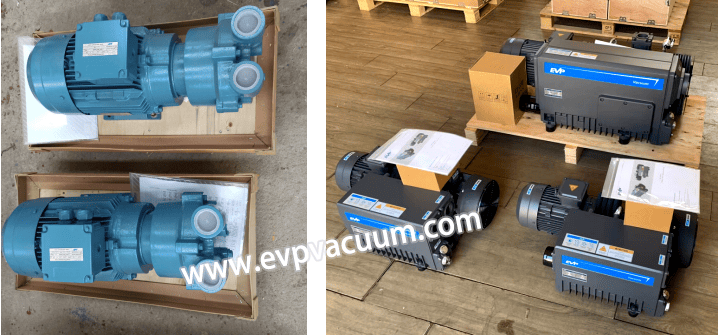

The performance of the vacuum pump determines the effect of wood grain transfer. Because of the requirements of high performance and high quality, EVP vacuum pumps are widely used by customers in vacuum wood grain transfer machines.

Vacuum wood grain transfer machine is applicable to: transfer steel-wood doors, anti-theft doors, fire doors, large iron doors, steel-wood door panels, stainless steel door panels, various door frames, cabinets, filing cabinets, decorative strips, and surface wood grain treatment of various steel products.

Process operation procedures

1.Preparation before production:

(1) Whether the power supply, voltage, compressed air pressure, and fan are running normally. Can the furnace temperature be met? Confirm that all equipment can operate normally before organizing production.

(2) Prepare the corresponding wood grain paper according to the production plan.

(3) There are no dust particles in the transfer furnace, and there is no dust in the work area.

2.Quality inspection (before loading):

(1) The surface quality and shape appearance of the produced profiles shall be inspected according to the “Internal Control Standard”. Profiles with surface quality defects such as bending, twisting, bubbles, and bumps shall be placed in the designated inspection area.

Check whether there are defects such as oil, stains, severe scratches, color difference, etc. on the surface of the profile that affect the quality of wood grain transfer. If there are any defects, they should be treated as unqualified (the oil stains can be wiped off with rags). Batches of more than 5 pieces shall be inspected and judged.

3.Heating in the furnace

The temperature of the empty furnace is set to 180-190℃, and the furnace body is quickly heated to a constant temperature. The time shall not be less than 1.2 hours. When heating, heat the operating table together for 10 minutes, then exit and load the material to reduce the temperature difference of the furnace body.

4.Paper laying

Covering film type:

1)Before laying paper, lay high-temperature resistant cloth strips at both ends according to the length of the profile. The part pressing the profile shall not exceed 2cm to prevent scratching the cloth.

2)Laying the wood grain transfer surface of the wood grain paper upward on the bottom of the operating table. The wood grain paper must be longer than the workpiece and sweep the wood grain paper flat.

Bag type:

1)Cutting the paper bag according to the size of the aluminum profile. Putting the aluminum profile into the paper bag. Generally, the bag is more than one-third larger before vacuuming.

2)Putting the profile on the cut bag and wrap it up and seal the edges.

5.Loading:

(1) The operator must ensure that there is no dirt on his hands or wear clean gloves. The profiles put on the shelf must be inspected and listed as qualified products.

(2) The profiles are placed flat on the shelf. The spacing between the profiles is determined by the circumference of the profiles. They cannot be placed on the shelf overlapping. The gap between the profiles must be ensured so that the workpiece can fully contact the wood grain paper.

(3) The vacuum suction tube on the processing bed cannot be placed on the workpiece, but can only be placed on the end of the profile.

6.Closing the lid

Open the air pressure switch for closing the lid, close the upper and lower parts together, and buckle the buckle.

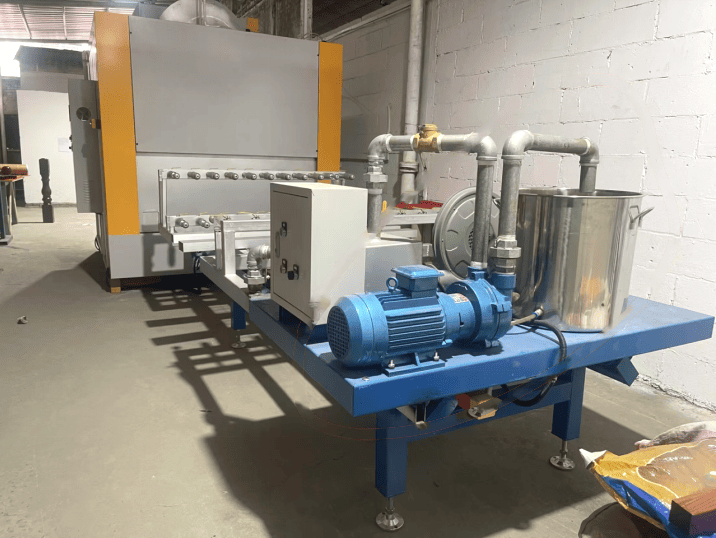

7.Vacuum Pump

When vacuuming process, slowly and gradually opening the vacuum switch and keeping the air pressure at 0.01~0.02MPa. At the same time, smooth the wrinkles on the upper and lower parts of the profile, and wipe the concave grooves and other difficult-to-contact parts of the workpiece with your hands to ensure that the wood grain paper is completely close to the profile, and then open the air pressure to 0.05~0.07MPa. The performance of the vacuum pump determines the fit of the wood grain. Usually, the 2BV series water ring vacuum pump of Shanghai EVP Vacuum or the SV series oil-lubricated rotary vane vacuum pump is selected:

8.Transfer Printing into the furnace

Open the furnace door, let the workpiece and workbench carrying the profile enter the transfer furnace, then set the transfer temperature at 175-185℃, and the constant temperature time is between 7 and 15 minutes (the set temperature and time refer to the process requirements of wood grain paper).

9.Remove from the furnace and unload the material

One minute before the constant temperature time is up, turn off the vacuum switch, and after the equipment automatically comes out of the furnace, open the cover pressure switch and lift out the transferred profile.

Vacuum Wood Grain Transfer Printing Machine are widely used in industrial production. In order to enable the vacuum pump to play a key role in the wood grain transfer machine, put it into production, reduce the occurrence of failures, and extend the service life of the equipment, daily maintenance is required:

1.The vacuum oil of the vacuum pump of the wood grain transfer machine needs to be replaced according to the working environment. If the working environment is poor (more dust), it needs to be replaced once every three months, and if the working environment is good, it needs to be replaced once every six months.

2.If you use oil-lubricated rotary vane vacuum pump, the air inlet is connected to the air filter, and the filter element in the air filter needs to be cleaned regularly. If the working environment is poor, it needs to be cleaned about once a month, and if the working environment is clean, it needs to be cleaned about once every three months.

The vacuum pump cannot be exposed to water during use, and water cannot be injected into the working plate of the machine. If water enters the vacuum pump, do not force the vacuum pump to work, and quickly contact the manufacturer for repair and maintenance.

If you selected the water ring vacuum pump, it is recommended to change the water regularly to remove internal impurities, if working vacuum is not better, please change spare parts or change new one.

3.Vacuum pump motor: if the machine needs to be moved. When rewiring is required, pay attention to the forward and reverse rotation of the vacuum pump motor! The motor cannot be reversed for a long time. If it is reversed for more than 20 seconds, the motor will burn out.

For more applications in the vacuum industry, please contact Shanghai EVP Vacuum Technology Co., Ltd.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)