Air cooled roots vacuum system

The field of vacuum acquisition equipment, in particular, relates to a fully air-cooled vacuum system .

Air cooled roots vacuum system technology:

With the development of technology and the improvement of product quality in aerospace, electric power, iron and steel processing, pharmaceutical and chemical industries, these industries need to obtain a certain vacuum environment. At the same time, the vacuum system used by these industries is continuously increasing, and the vacuum degree is continuously increasing. Moreover, the state’s environmental protection, energy saving and three wastes discharge to the above-mentioned industries, etc. The requirements are more stringent. At present, the existing dry vacuum pumps on the market, such as screw vacuum pumps and claw vacuum pumps, are unable to meet the requirements of oil-free large pumping speed clean vacuum environment proposed by these industries due to the restrictions of pumping speed characteristics and structural mechanism.

In view of the shortcomings of the existing technology, the technical problem to be solved by the utility model is to provide an all-gas-cooled vacuum system to satisfy the use in a clean vacuum environment with large oil-free pumping speed.

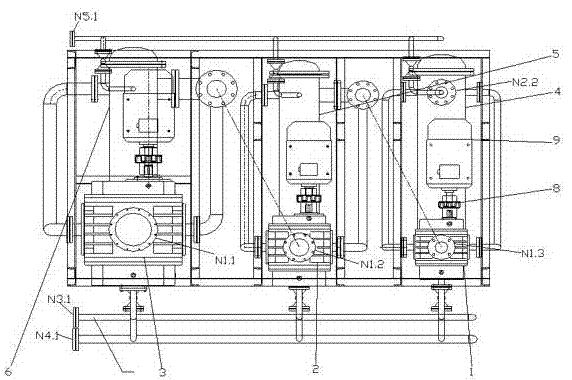

In order to solve the above technical problems, the technical scheme adopted by the utility model is an all-gas-cooled vacuum system , including a base, which is equipped with a front-stage unit, an intermediate unit and a main engine group; the front-stage unit includes a front-stage pump and a front-stage pump heat exchanger, and the intermediate unit includes an intermediate pump and a middle pump heat exchanger, and a main engine package. It includes the main pump and the main pump heat exchanger; the exhaust port of the front pump is connected with the intake port of the heat exchanger of the front pump, and the heat exchanger of the front pump is provided with three exhaust ports of the heat exchanger of the front pump. Two of the intake ports of the heat exchanger of the front pump are respectively connected with the cold gas intake on both sides of the front pump body. The exhaust port is connected with the intake port of the heat exchanger of the intermediate pump. The heat exchanger of the intermediate pump is provided with two exhaust ports of the heat exchanger of the intermediate pump. One of the exhaust ports of the heat exchanger of the intermediate pump is connected with the intake port of the front pump. The two exhaust ports of the heat exchanger of the intermediate pump are respectively connected with the cooling gas on both sides of the intermediate pump. The main pump heat exchanger is provided with two main pump heat exchanger exhaust ports, one of the main pump heat exchanger exhaust ports of the main pump heat exchanger is connected with the air inlet of the intermediate pump, and the two exhaust ports of the main pump heat exchanger are respectively connected with the cooling air on both sides of the main pump body. Body inlet connection.

Optimized, the whole gas-cooled vacuum system , the front pump, the middle pump and the main pump are three-leaf gas circulating cooling Roots vacuum pumps.

Optimized, the all-gas-cooled vacuum system has a muffler connected with the air inlet of the heat exchanger of the front-stage pump which is not connected with the cooling gas inlet of the front-stage pump, and the muffler is directly connected with the atmosphere.

The air inlet butterfly valve of the main air pump is connected with the pneumatic butterfly valve.

Optimized, a pressure transmitter is arranged between the air inlet of the main pump and the pneumatic butterfly valve of the all-gas-cooled vacuum system .

Optimized, the all-gas-cooled vacuum system is connected with an empty outlet between the front pump heat exchanger, the middle pump heat exchanger and the main pump heat exchanger.

Optimized, the all-gas-cooled vacuum system is connected with a water inlet and a drainage outlet by the front pump heat exchanger, an intermediate pump heat exchanger and a main pump heat exchanger.

Optimized, the air-cooled vacuum system is connected with a water inlet and a drainage outlet by the front, middle and main pumps.

The utility model has the advantages of overcoming the disadvantages of the prior art, and having reasonable and novel structural design. The air-cooled Roots vacuum unit uses the air-cooled Roots pump as the front pump, the middle pump and the main pump, which can realize the oil-free condition of the vacuum pumping system and meet the application requirements of various occasions. Compared with other dry pumps such as screw pump and claw pump, the air-cooled Roots pump has the advantages of large pumping capacity, fast start-up, short time to reach pre-pumping pressure and low energy consumption. Taking air-cooled Roots pump as intermediate pump and main pump, the motor power, cooler size and circulating water volume of air-cooled pumps are selected according to different working conditions such as field pressure, pumping time and pumping rate. Because the three-blade rotors of air-cooled Roots pump do not contact each other when rotating, the unit has the advantages of smooth operation, low noise, small vibration, compact structure and small floor area. Compared with claw pumps and screw pumps, all-gas-cooled Roots vacuum unit has obvious energy-saving effect, large vacuum pumping capacity and high vacuum degree. The all-gas-cooled vacuum system can be widely used in aerospace, electric power, steel treatment, pharmaceutical and chemical industries, especially in clean vacuum, oil-free steam pollution industry, as well as in occasions containing a large amount of water vapor and a small amount of dust.

EVP supplies air-cooled vacuum system s. If you want to know more about our vacuum pump products, or if you want to consult vacuum pump materials, please leave a message or send an email to contact@evpvacuum.com.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)