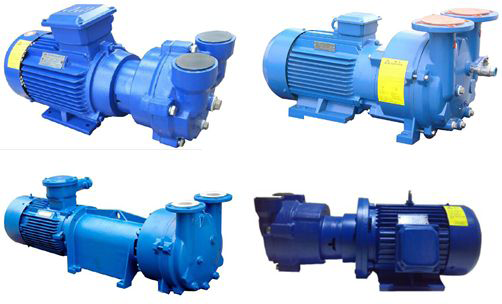

Application of water ring vacuum pump in oil depot

The water ring vacuum pump in the oil depot shall be used to vacuum the centrifugal pump and the suction system to guide the oil tank pump. And use it to pump the residual oil from the bottom of the tank car. For any vacuum pump, the following main parameters are used to indicate the working performance.

(1) extraction rate

The extraction rate refers to the volume of air space that the vacuum pump inhales from the inlet pipe under residual pressure in unit time, namely the production capacity (or flow Q) of the vacuum pump, expressed as m cubed /h or L/S.

(2) residual pressure or limit vacuum residual pressure or limit vacuum degree refers to the minimum absolute pressure that the pump can reach.

With a vacuum pump, the gas in a closed container can be pumped. No matter how long it takes, the pressure in the container cannot be reduced to zero indefinitely, that is, absolute vacuum. This is because the gas pressure is lower than a certain value, or due to vaporize liquid in the pump, or because of the high pressure sliding sideways to air and vacuum pump swept volume is the same, or a high vacuum pump compression volume coefficient reduced to 0, can make the pump in fact cannot continue to absorb people fresh gas. The pressure in the container will never be reduced in this case, and the absolute pressure value is called residual pressure or ultimate vacuum.

Water ring vacuum pump primer tank pump in use with the tank, the vacuum tank and the pipeline composition of a system.

Water ring type vacuum pump primer tank pump operation process:

1. Before opening the pump, open the irrigation valve, and fill the water supply box and the vacuum pump respectively until the overflow of the overflow pipe, and close the valve.

2. Close the valve connected to the vacuum tank pipe and open the valve on the water ring pump to close the ball valve and start the vacuum pump.

3. after opening pump, vacuum pump vacuum tank gas extraction, and part of the gas inside the pump into the water tank with water. Air and water in the tank after separation by the exhaust pipe line to the atmosphere, water valve 8 can be recycled.

4. after waiting for vacuum tank reaches a certain vacuum degree 1 open the valve, vacuum pump and pump suction system of air, when resistance oiler have feed sound or vacuum tank when we have a small amount of oil into the irrigation pump has been finished, close the valve, stop the pump priming.

5. Before stopping the pump, the valve of water ring pump should be closed, and the air valve should be opened, and then the pump should be stopped to prevent the liquid rest in the pump from being sucked into the vacuum tank.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)