Carbon Capture Vacuum Pumps

Carbon Capture Vacuum Solution

Climate change is a fact that cannot be ignored. Our dependence on fossil fuels has led to an increase in the concentration of carbon dioxide in the atmosphere, which is one of the main causes of global warming. The development of industry and our consumption of oil, coal, and natural gas are releasing carbon dioxide that has been stored for millions of years. To overcome this problem, carbon capture, utilization, and storage (CCUS) technology is being developed worldwide. These technologies aim to reduce carbon dioxide emissions and even lower the existing concentration of carbon dioxide in the atmosphere. Its main goal is to capture carbon dioxide from factory emissions or directly from the air, and use it to replace fossil fuels or store it to reduce the concentration of carbon dioxide in the atmosphere.

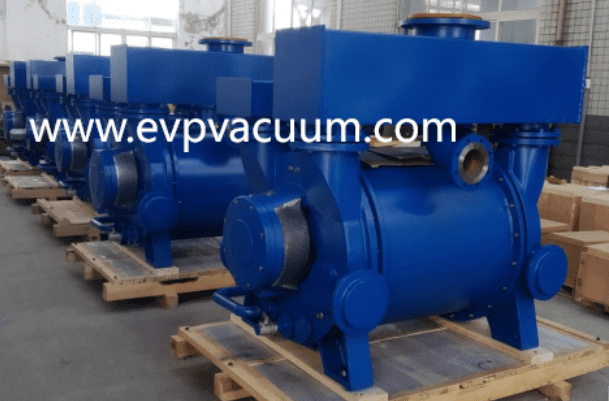

The liquid ring vacuum pump is available in a stainless steel structure version, which is very suitable for carbon capture during this process.

In which carbon capture processes does vacuum play a role?

The scientific community is researching various methods for capturing, storing, and reusing carbon, and for most technologies, vacuum is an important link. Some of the technologies being tested by various companies include:

Pre treatment of fossil fuels and carbon capture before combustion

One of the most advanced carbon capture technologies is to capture carbon immediately upon discovery in downstream factories. Capturing carbon dioxide directly from raw materials can prevent its release into the atmosphere during combustion.

Fossil fuels such as natural gas can be converted into a gas mixture of hydrogen and carbon dioxide (CO2) through the “gasification” process. This process involves converting fossil fuels into a gas mixture of hydrogen and carbon dioxide (CO2). Then, the gas mixture is treated using a conversion reaction to convert most of the carbon dioxide into carbon monoxide (CO) and hydrogen gas. Then, the generated gas mixture is treated using pressure swing adsorption technology or other appropriate techniques to separate carbon dioxide from hydrogen. This is the stage of applying vacuum technology.

The separated carbon dioxide can be stored or used in other industrial processes, while purified hydrogen can become a clean energy source. Pre combustion carbon capture is a commonly used technology in integrated gasification combined cycle power plants, which can significantly reduce carbon dioxide emissions while providing energy.

Carbon capture process after combustion

These processes use solvents or adsorbents to capture carbon dioxide from industrial “flue gas”, and then use vacuum to remove the captured carbon dioxide from the solvent. This process is called “gas stripping” or “regeneration”. Once carbon dioxide is released and collected, it can be stored for further use.

Direct Air Carbon Capture Technology (DAC Carbon Capture)

This technology utilizes solid adsorbents or adsorbents regenerated under vacuum conditions to capture carbon dioxide from ambient air. This regeneration process releases captured carbon dioxide for collection, which is similar to the way carbon is treated after combustion.

Which vacuum pump technology is used in the carbon capture process?

Capturing and removing carbon dioxide almost always involves adsorption filtration technology – physical adsorption or chemical adsorption, regardless of which stage carbon capture occurs. Some of these technologies include:

VPSA (Vacuum Pressure Swing Adsorption)

Membrane separation process

Using amine chemicals for chemical cycling