Brand: EVP

Classification: Socket board Valves

Availability : In Stock

CC series ultra-high vacuum flapper valve by hand wheel with screw drive, the drive lever (pull) dynamic link mechanism, drive along the axial movement of the valve plate, achieve the valve open or closed, so as to achieve ultra-high vacuum system object on or off the air flow.

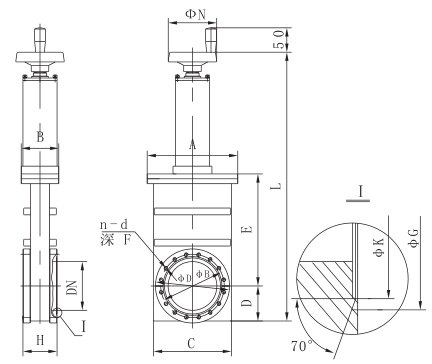

Outline dimension and connection size

| Model | Nominal diameter (DN) | Dimensions | Flange size | ||||||||||||

| A | B | C | D | E | H | L | ΦN | ΦD | ΦB | ΦG | ΦK | n-d | F | ||

| CC-63 | 63 | 130 | 64 | 110 | 54 | 170 | 66 | 380 | 100 | 114 | 92.2 | 82.4 | 77 | 8-M8 | 12 |

| CC-80 | 80 | 166 | 77 | 140 | 61 | 210 | 70 | 530 | 130 | 110 | 99 | 93 | 16-M8 | ||

| CC-100 | 100 | 186 | 160 | 72 | 230 | 72 | 552 | 152 | 130.3 | 120.6 | 115 | ||||

| CC-150 | 150 | 234 | 78 | 207 | 96 | 307 | 78 | 673 | 125 | 202 | 181 | 171.4 | 166 | 20-M8 | 15 |

| CC-200 | 200 | 280 | 98 | 254 | 121 | 382 | 80 | 776 | 253 | 231.8 | 222.1 | 217 | 24-M8 | ||

| CC-250 | 250 | 342 | 117 | 312 | 148 | 462 | 92 | 892 | 200 | 305 | 284 | 273.1 | 267 | 32-M8 | |

| CC-320 | 320 | 449 | 425 | 212 | 670 | 130 | 1196 | 425 | 338.1 | 326.4 | 320 | 32-M10 | 18 | ||

| CC-400 | 400 | 536 | 512 | 256 | 810 | 130 | 1391 | 512 | 437.9 | 424.4 | 419 | 40-M10 | |||

CC series ultra-high vacuum flapper valve by hand wheel with screw drive, the drive lever (pull) dynamic link mechanism, drive along the axial movement of the valve plate, achieve the valve open or closed, so as to achieve ultra-high vacuum system object on or off the air flow. In the structural design is reasonable, beautiful in appearance, and has a smooth operation, small size, flow rate, reliable, good sealing performance and long life, etc., it can be widely used in ultra-high vacuum equipment.

Suitable working medium is clean air and non-corrosive gases.

| Applicable range (Pa) | 105~1.3×10-7 |

| Gas leakage rate (Pa.L/S) | DN≤200for≤1.3×10-7 |

| DN≥250for≤6.7×10-7 | |

| Valve”s roasting temperature(℃) | ≤150(Except the drive device) |

| Pressure difference when opening the valve”s plates (Pa) | ≤2.7×103 |

| Valve plate”s sealing meaterial | Fluorous rubber |

| Sealing material for spindle seal | Stainless steel bellows |

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.