Brand: EVP

Classification: Dry Type Oilless Vacuum Pumps

SUCTION CAPACITY:12L/S TO 1000L/S

VACUUM RANGE: 2X10-9PA

Availability : In Stock

EVP Series Sputtering Ion Pump products are specially designed for ultra-high vacuum users, which can be widely used in various ultra-high vacuum scientific research equipment and industrial equipment.

Technical Data:

| Item | Technical Specifications | ||||

| Model | SIP10 | SIP25 | SIP50 | SIP100 | |

| Nominal Capacity(l/s) |

S-ASD | N2 15(at1x10-5pa) | 35(at1x10-5pa) | 80(at1x10-5pa) | 140(at1x10-5pa) |

| N2 12(at1x10-7pa) | 30(at1x10-7pa) | 70(at1x10-7pa) | 120(at1x10-7pa) | ||

| Ar 3(at1x10-7pa) | 10(at1x10-7pa) | 25(at1x10-7pa) | 48(at1x10-7pa) | ||

| U-ASL | N2 15(at1x10-5pa) | 32(at1x10-5pa) | 75(at1x10-5pa) | 130(at 1×10-5pa) | |

| N2 11(at1x10-7pa) | 30(at1x10-7pa) | 65(at1x10-7pa) | 120(at 1×10-7pa) | ||

| Ar 15(at 1×10-7pa) | 15(at1x10-7pa) | 35(at1x10-7pa) | 65(at1x10-7pa) | ||

| Ultimate Pressure | S-ASD | ≤ 5X10-8pa | ≤ 2X10-8pa | ≤ 5X10-9pa | ≤ 3X10-9pa |

| U-ASL | ≤ 3X10-8pa | ≤ 1X10-8pa | ≤ 2X10-9pa | ≤ 1X10- 10pa | |

| Starting pressure | ≤ 1X10-2pa | ≤ 1X10-2pa | ≤ 2X10-2pa | ≤ 2X10-2pa | |

| Anode voltage(kv) | ≤+7(dv) | ≤+7(dv) | ≤+7(dv) | ≤+7(dv) | |

| Connecting flange | CF35 | CF35 | CF63/CF100 | CF100 | |

| Noise | <55dB | <65dB | <65dB | <68dB | |

| Baking temperature℃ |

≤300 | ≤300 | ≤300 | ≤300 | |

| Built-in baking power | 0.08(optional) | 0.18(optional) | 0.2 | 0.28 | |

| Dimension (LXWXH)mm |

130x150x110 | 173x134x210 | 244x162x234 | 309x162x315 | |

| Weight | 10Kg | 14Kg | 25Kg | 38Kg | |

| Item | Technical Specifications | ||||

| Model | SIP200 | SIP400 | SIP600 | SIP1000 | |

| Nominal Capacity(l/s) |

S-ASD |

N2 230(at1x10-5pa) | 430(at1x10-5pa) | 600(at1 x10-5pa) | 1000(at1x10-5pa) |

| N2 200(at1x10-7pa) | 420(at1x10-7pa) | 460(at1x10-7pa) | 830(at1x10-7pa) | ||

| Ar 60(at1x10-7pa) | 100(at1x10-7pa) | 140(at1x10-7pa) | 210(at1x10-7pa) | ||

| U-ASL | N2 230(at1x10-5pa) | 420(at1x10-5pa) | 580(at1x10-5pa) | 1000(at1x10-5pa) | |

| N2 200(at1x10-7pa) | 350(at1x10-7pa) | 460(at1x10-7pa) | 820(at1x10-7pa) | ||

| Ar 80(at1x10-7pa) | 160(at 1×10-7pa) | 200(at1x10-7pa) | 350(at1x10-7pa) | ||

| Ultimate Pressure | S-ASD | ≤ 2X10-9pa | ≤ 2X10-9pa | ≤ 2X10-9pa | ≤ 2X10-9pa |

| ≤ 7X10- 10pa | ≤ 5X10- 10pa | ≤ 9X10- 10pa | ≤ 9X10- 10pa | ||

| U-ASL | |||||

| Starting pressure | ≤ 2X10-2pa | ≤ 2X10-2pa | ≤ 2X10-2Pa | ≤ 2X10-2Pa | |

| Anode voltage(kv) | ≤+7(dv) | ≤+7(dv) | ≤+7(dv) | ≤+7(dv) | |

| Connecting flange | CF150 | CF150 | CF200 | CF200 | |

| Noise | <55dB | <65dB | <65dB | <68dB | |

| Baking temperature℃ |

≤300 | ≤300 | ≤300 | ≤300 | |

| Built-in baking power | 0.62 | 0.68 | 0.8 | 1.2 | |

| Dimension (LXWXH)mm |

442X188X445 | 442X244X445 | 492X330X452 | 585X520X452 | |

| Weight | 66Kg | 96Kg | 130Kg | 215Kg | |

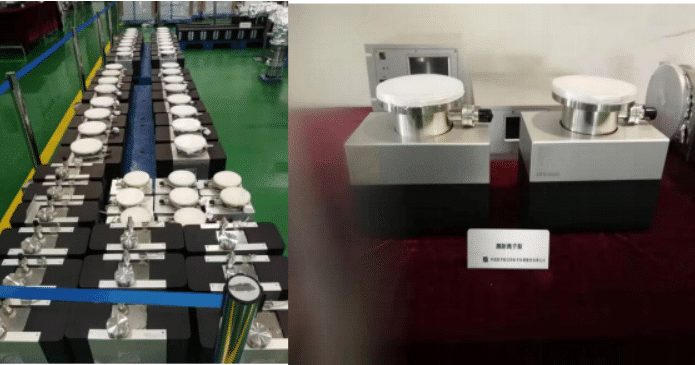

Pump pictures

Main Applications:

EVP Series Sputtering Ion Pump products are specially designed for ultra-high vacuum users, which can be widely used in various ultra-high vacuum scientific research equipment and industrial equipment.

The industries involved are instruments, particle accelerators, synchrotron radiation sources, high-power laser research, Surface physics, materials science, space simulation, electron microscope, mass spectrometer, communication, vacuum calibration, vacuum smelting, vacuum coating, semiconductor application equipment, vacuum electronics, medical and other industries.

Advantage:

1.The structure of EVP series Sputtering Ion Pump adopts simulation and optimized design, and has a pumping capacity of not less than 85% of the nominal pumping speed under the vacuum condition of 1×10-7pa.

2.In the extremely high vacuum (XHV) region, the Sputtering Ion Pump still has a large pumping capacity. Use a testing device that meets national testing standards to get a minimum testing pressure of 3.6×10 – 10 Pa. With the optimized design of the high-end SIP400A sputtering ion pump, the lower limit of the extreme pressure test has entered 10- 11Pa.

3.High-quality raw materials, such as special insulation materials, which are resistant to high voltage and high temperature.

4.The entire pump uses a special anti-corrosion coating, which enables the ion pump to remove various corrosive gases, can withstand high temperatures, and prolong the service life of the pump in harsh environments.

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.