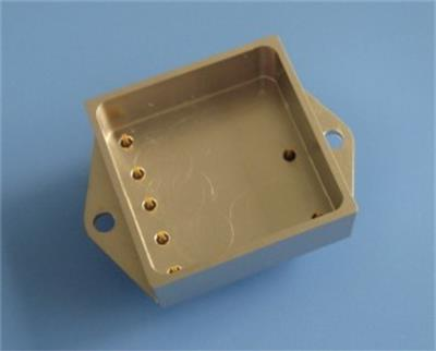

Helium Leak Detection for Metal Encapsulation Shell

Helium Mass Spectrometry Leak Detection for Metal Encapsulation Shell of Application

With the development needs of various electronic industries, metal packaging shells are widely used in military and civilian fields such as aerospace, aviation, navigation, field operations, radar, communication, weapons, etc. As one of the key components of integrated circuits, the casing mainly plays a role in circuit support, electrical signal transmission, heat dissipation, sealing, and chemical protection. In terms of its impact on circuit reliability and proportion of circuit cost, the casing occupies an important position. The requirement for sealing is extremely high, and the shell is sealed. Once there is a leak, the entire chip will fail!

Helium leak detection is the use of helium gas to inspect small leaks on electronic component packaging shells. Due to the small size of helium atoms, it is easy for them to pass through small holes and enter the interior of the tube shell. Therefore, this detection method can detect small holes with a leakage rate of about 1011~10-13 cm2/sec, and its sensitivity can rival that of radioactive leak detection methods, but it is simpler than radioactive leak detection methods.

(Metal casing)

The metal packaging shell needs to undergo leakage testing for its own sealing performance Due to the small size of packaged devices and the inability to vacuum or directly fill them with helium gas, it is recommended to use a helium mass spectrometer leak detector “back pressure method” for leak detection,

The specific method is as follows:

1. Place the inspected packaged device into a vacuum pressure tank, and set the pressure and time according to the leakage rate

2. Remove the sealed casing and blow the surface with helium gas using air or nitrogen

3. Place the packaging shell into a vacuum leak detection tank, and connect the leak detection tank to the helium mass spectrometer leak detector inlet

4. Start the helium mass spectrometer leak detector and set the leak rate value to 5 × 10-10Pa • m3/s in vacuum mode for leak detection

(Helium Leak Detection)

The helium mass spectrometer leak detector has been widely used in many industries due to its excellent quality and stable performance, meeting various industry applications. The company has established a comprehensive after-sales service system and implemented a 24-hour response system, providing strong guarantees for the stable operation of products.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)