Helium leak detector used in vacuum coating machine leak detection

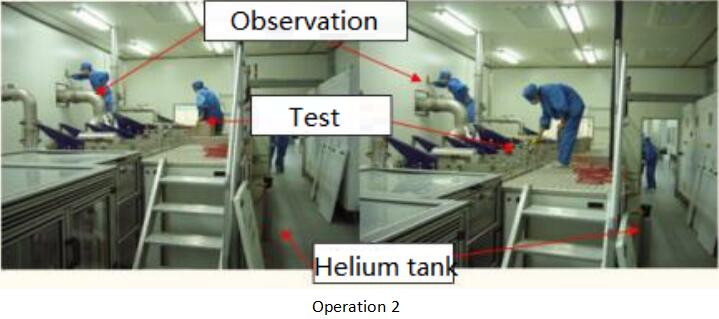

When the vacuum coating machine is leaking, when the vacuum inside the coating machine drops to a certain level, such as below 0.5 mbar, spray helium gas on the suspected leak, or check the parts moved during standard maintenance. At this time, it is necessary to Someone observes the change of the leak rate indication value of the leak detector. When the leak rate rises or the leak rate value changes drastically, point out the location of the leak point in time and make a mark.

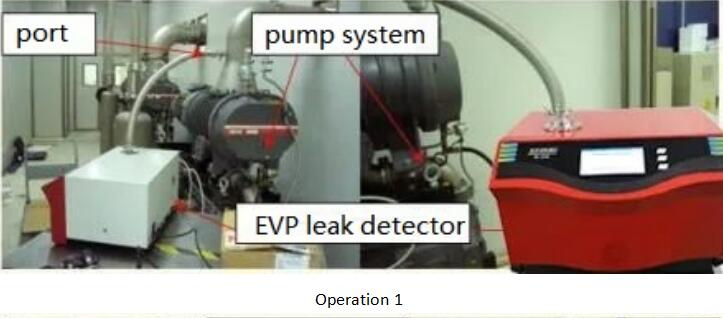

The schematic diagram is as follows:

1) Connect the helium mass spectrometer leak detector EVP brand SFJ-261 to the leak detection port in front of the pump set.

2) Start the leak detector, the leak detector starts to extract the gas in the closed cavity, and at the same time starts the pump set of the coating equipment.

3) When the vacuum inside the coating machine drops to a certain level, such as below 0.5 mbar, spray helium gas on the place where there is suspected leakage, or check the parts moved during standard maintenance. At this time, someone needs to observe the inspection. The change of the leak rate indication value of the leak meter. When the leak rate rises or the leak rate value changes drastically, point out the location of the leak point in time and make a mark.

4) After all suspicious points are detected, turn off the leak detector, stop the pump set of the coating machine and turn on the coating machine, and process the detected leak points (such as replacing the sealing ring, cleaning, etc.). The processing is completed After that, check it again according to the previous steps until all leaks are cleared, and the leak detection process is completed.

For more information on EVP’s leak detectors, please see:

https://www.evpvacuum.com/evp-helium-mass-spectrometer-leak-detector.html

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)