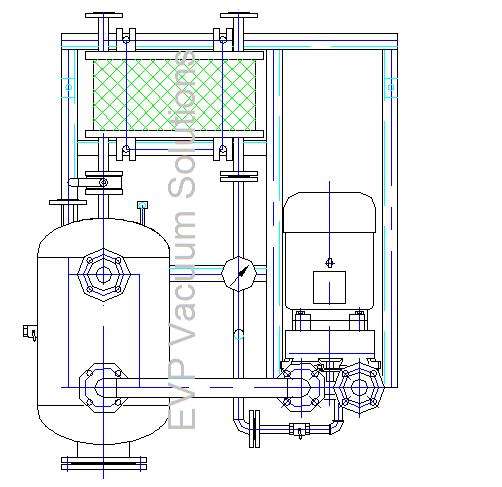

2BV5-111 closed-loop circulation vacuum unit

1. General Instruction

Liquid ring vacuum pump unit as a single pump system to expand to lots of applications. Which have been widely used in the coal, pharmaceutical, chemical, power and other industries to provide customers with more humane services, easier operation, more timely monitoring. However, as a non-standard products, each vacuum unit with different configurations, this manual has some limitations, which only used for this designed vacuum unit .Refer to routine operation, inspection, preparation, etc. of each liquid ring vacuum pump, please refer to the “liquid ring vacuum pump instruction manual” .

2. Vacuum Units Applications

a, Due to the operation of liquid ring vacuum pump requires a lot of water, if in the water shortage, or local water quality is hard, long-term operation with serious water-scale occasions, normally we recommend choose the closed-loop circulation liquid ring vacuum pump units, the liquid of unit has always been use soft water to operate it;

b, When the extraction of flammable and explosive gases, or circulating fluid containing toxic and harmful media, or in the cleaning occasion required the gas/ liquid in recovery and not allowed to emit directly, we still recommend the closed-loop circulation liquid ring vacuum pump units;

c, When the performance parameter of single pump can not meet the requirements, or under the production which not allowed to stop, it can be used the series type, parallel type, one open pump with one standby pump type, or more open’s with more standby’s types to compose the vacuum units;

d, When the ultimate vacuum pressure of requested are higher but the performance of single pump can not meet the technical requirements, it can be used the Roots booster vacuum pump to compose to Roots booster – liquid ring vacuum pump units so that to improve the limit vacuum pressure of system;

e, When used in compressor conditions, the liquid ring vacuum pump must be equipped with a postpose pressure vessel for gas-liquid separation, and the best case is to be designed into vacuum units to operate in such occasion;

f, When the system contains a lot of water, gas or other impurities, it is recommended to use a pre-separator tank plus vacuum pumps to compose vacuum units, which is the most simple unit configuration and commonly used in the mineral processing industry, such as match filtering machines to operation;

g, All those industries and occasions which can be used in liquid ring vacuum pumps, in order to improve the system and pump monitoring level, and convenient to control as well as reduce the error of manual operation , still recommended selection the complete vacuum units.

3. Working Principle

Working Principle of liquid ring vacuum pump

Liquid ring vacuum pumps have two types : single stage type and double stages types. They are are mainly used to extract the gases and the vapors which lower atmospheric pressure. The impeller on the shaft is eccentrically mounted in a cylindrical pump body and rotates therein, the rotation of the impeller causes the working fluid to form a rotating water circle in the pump body, the water circle pulsates between the two blades of the impeller. In the suction side, the water circle gradually away from the impeller hub, the gas through the suction hole on the port plates go into the pump chamber; in the exhaust side, the leaf ring and gradually close to the impeller hub, the gas is compressed and through the disc The air port is axially discharged; in the exhaust side, the water circle gradually close to the impeller hub, the gas is compressed and through the discharge hole on the port plates to exhaust axially.

Note: The liquid ring vacuum pump referred to in this manual should theoretically called “water ring vacuum pump” because of working fluid media in water. Except water can be used circulated medium, the oil or other organic media.

4. Configurations

Each vacuum unit has different demanding with different applications, therefore the configurations are also different. The definition of vacuum unit is for single pump, even if a single pump plus a gas-water separator can also be called vacuum unit, but this is a relative simple vacuum unit. This manual will be listed all its related accessories for end user selection, daily using and equipment maintenance for reference.

(1)Vacuum Unit Common Configurations (refer to Technology Agreement)

Liquid ring vacuum pump + transmission type + motor + gas-water separator + base plate + heat exchanger + instruments + valves & pipelines

5. Operating Instruction

1. Please refer to the vacuum system diagram, below is the operating instructions:

(1) Check the pipeline and make sure all is clearing without residue and other residual solid particles exist before starting pump;

(2) Check all the valves in pipeline are installed in correct place, no blocking on the water pipelines and gas pipelines, the cooling water of heat exchanger on the water indicating level;

(3) Through the manual valve NO.3 to fill water to the separator, then check no water leakage phenomenon (because the factor process may be loose), after closing the water valve, the water level of separator would better stay in the pump center line; pay attention to the replenishment water process, the wire block at the top of liquid level meter should be open and closed it when ended the water replenishment;

(4) Calibration the test instruments;

(5) Start the motor of liquid ring vacuum pump and check the rotation way is same with the indicating label;

(6) Starting the liquid ring vacuum pump, checking the suction port of pump to reach vacuum environment and appropriately adjust the inlet pipe valve (from the heat exchanger into the pump valve, generally not fully open, otherwise the water volume is too large and the current increases, suction capacity decreases);

(7) During the operation, the vacuum gauge on the inlet tube of vacuum unit shows the reading so that to meet the processing requirements;

(8) The unit shall operate normally and check the sound also is normal;

(9) When the unit is running, pay attention to the water level of the pump, the water level and water temperature are not too high; It is necessary to check whether the vacuum gauge is stable and can meet the production process requirements;

(10) Cut off the valves ( the valve on the suction port No.1 and discharge port No. 2) on the main pipelines before shutting down the vacuum unit and turning off the power supply so that to prevent backwater, then stop the pump; After stopping the pump, open the pump, the negative pressure tank and all valves on pipelines in manually, drain out the working liquid, check each spare parts in regularly.

(11) Under the permission conditions, the lower temperature of cooling water for Heat exchanger, the better performance for liquid ring vacuum pump. As the performance curve of liquid ring vacuum pump is obtained at 15 degrees water temperature, the vacuum unit circulating water through the heat exchanger after cooling should be maintained below 25-30 degrees. The circulating water should not add too much in the first commissioning for vacuum unit, it is best to gradually increase the working liquid until meet the process requirement.

(12) Related accessories debugging and maintenance, such as valves, please refer to its relevant product manual.

tags: liquid ring vacuum pump, Closed Cycle Water Ring Vacuum System

Edited by Catherine Qin / EVP Vacuum Solution