helium mass spectrometer leak detector in leak detection of aircraft wing integral fuel tank

The sealing of the wing integral fuel tank is a key technology in the manufacturing of wing boxes, and its sealing performance directly affects the service and safety of the aircraft. The wing integral fuel tank has a large volume and high sealing requirements. Traditional leak detection methods use airtight and oil tight tests, which have disadvantages such as low accuracy, high cost, difficult quantification, and low efficiency. Moreover, conducting oil tight tests requires injecting a large amount of aviation kerosene into the integral fuel tank, which poses a huge safety hazard in the absence of dedicated oil tight explosion-proof workshops and dedicated oil tight test benches.

Therefore, there is an urgent need for an advanced leak detection technology with high detection accuracy, efficiency, safety, and reliability to overcome the above difficulties and improve the manufacturing level and production efficiency of the overall fuel tank.

Leak detection instructions for the overall fuel tank of aircraft wings

The integral fuel tank adopts an integral design and assembly, that is, the integral wall panels, beams, and ribs are connected by high lock bolts. The internal ribs have through holes, and the front and rear beams of the wing do not have holes. The interlayer of the high lock bolts is sealed with sealant to form a sealed wing box. In actual production, due to various uncertain factors, the sealing performance of some bolts and interlayer cannot meet the requirements, resulting in oil leakage.

We are a professional manufacturer specializing in the development and production of vacuum equipment and helium mass spectrometer leak detectors. With years of innovation in the application and promotion of helium mass spectrometer leak detectors, we have been striving to promote the development of vacuum leak detection technology in China.

In order to solve this problem, it is necessary to conduct a sealing test on the fuel tank, identify accurate leakage points, and repair them. Using test specimens to explore the leakage rate of the wing’s overall fuel tank, the leakage test of the overall fuel tank test specimen is generally divided into two parts: one is coarse leakage point detection and process repair; the other is helium mass spectrometry fine leakage detection

Helium mass spectrometer leak detector in leak detection of aircraft wing integral fuel tank of application

The main equipment involved in the rough leak detection process includes compressed air source, automatic gas distribution platform, control valve, etc. During the test, the compressed air source is first connected, the overall fuel tank rapid leak detection equipment is started, and the inflation pressure is set. After the inflation process is completed, the pressure is stabilized for 15 minutes, and the pressure drop curve on the leak detection equipment is observed to determine whether there is a rough leak. If the pressure drop is obvious, it indicates the existence of a rough leak point. After determining the location of the rough leak point by soap bubble method, the rough leak point is repaired by applying sealant. After repeated testing and repair, helium mass spectrometry fine leak detection can be carried out until the pressure drop of the fuel tank test piece meets the technical requirements within the specified time.

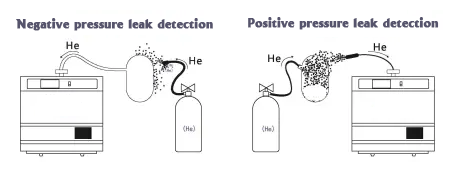

The fine leakage points of the fuel tank test piece are detected by positive pressure method. During the test, a mixture of helium gas and compressed air is filled into the interior of the fuel tank test piece to make the pressure inside the fuel tank greater than the external atmospheric pressure. If there is a leakage point, helium gas leaks out through the leakage point and can be detected by a suction gun to determine whether there is a leakage. The detection process should ensure that a cover box is added to the suction gun. Firstly, to prevent the helium concentration in the environment from being too high, which affects the detection; secondly, to prevent a large number of leakage points from leaking at the same time, the exact location of the leakage point and the leakage rate of a single leakage point cannot be detected. During the detection, the suction gun should slowly move along the suspicious leakage point to detect the accurate reaction value of the leakage source.

Helium mass spectrometer leak detector of advantages

In the overall fuel tank leak detection of aircraft wings, helium mass spectrometer leak detector has the following advantages:

High sensitivity: able to detect extremely small leaks, ensuring the sealing of the fuel tank.

High accuracy: By detecting the strength of the helium signal to determine the leakage situation, the results are accurate and reliable.

Fast response speed: able to complete the detection process in a short time, improving detection efficiency.

Good safety: Helium is an inert gas that will not cause damage to fuel tanks and aircraft.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)