helium mass spectrometer leak detectors with detecting leaks for common methods

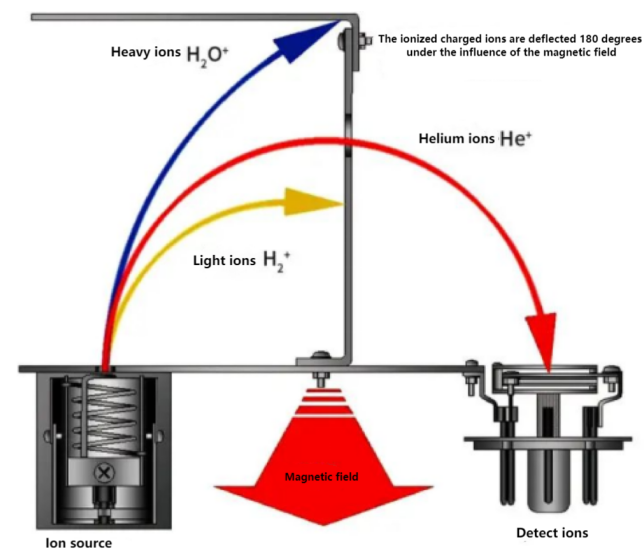

01 Helium mass spectrometer leak detector of principle

A helium mass spectrometer leak detector is an instrument commonly used to detect small leaks in vacuum systems or sealed systems. The principle is based on the low permeability and high sensitivity of helium.

The gas mixed with the leaked helium reaches the ion generator in the helium mass spectrometer leak detector and is ionized by the electron beam emitted by the filament. After being accelerated by a specific voltage, the ions fly towards the magnetic field in the helium detector and are deflected. According to the difference in mass, different deflection radii are obtained, and helium ions are screened out and reach the analysis tube to generate a microcurrent. After high-performance and low-noise amplification, a readable current signal is obtained. The leakage rate relationship is established through calibration to determine the leakage rate.

02 Why is helium used as a tracer gas?

Helium mass spectrometer leak detectors use helium as the tracer gas for the following reasons:

(1)Low background noise:

The content in the atmosphere is small, only 5ppm, and 5ppm is five parts per million.

(2)Low permeability:

Helium is a very small molecule with high permeability, easily passes through small pores, and exhibits reverse diffusion. . This means that even in tiny leaks or cracks, helium can quickly diffuse and enter the detector for detection.

(3)Inert gas:

For product, site and personnel safety. Helium is an inert gas and does not react chemically with other substances. This can prevent helium from reacting with materials in the system under test, affecting the test results, and greatly improves operator safety.

(4)Ease of detection:

Helium has unique mass spectral characteristics in mass spectrometers, such as a mass number of 4 and high relative abundance. This allows the mass spectrometer to detect minute amounts of helium with high sensitivity, allowing it to accurately determine the location and size of the leak.

In summary, helium as a tracer gas has the advantages of good permeability, inertness, easy detection and wide application in helium mass spectrometer leak detectors, so it is widely used for leak detection.

03 Helium mass spectrometer leak detectors for commonly used leak detection methods

Commonly used helium mass spectrometer leak detectors have the following leak detection methods, each method has its own advantages and applicable scenarios:

- Vacuum leak detection method of spray gun:

Leak points can be located. With high precision. Consumes less helium. Mainly used in precision instruments, pressure vessels and other fields.

- Suck gun method:

Leak points can be located. No need to vacuum. Mainly used for leak detection in power plants and leak detection in aerospace rocket air control systems. A typical application is heat exchanger leak detection.

- Cumulative vacuum leak detection:

With high precision. Overall leakage can be measured. Online testing is convenient. Highly repeatable. A typical application is leak detection of fire equipment cylinders.

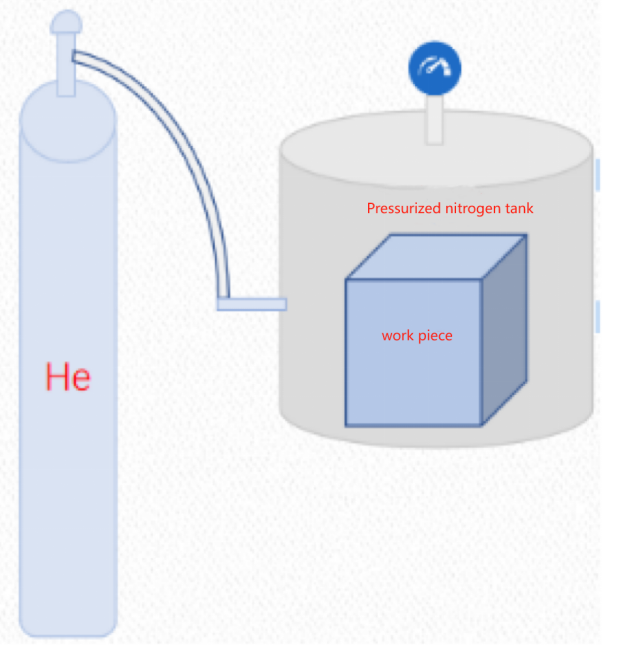

- Back pressure method:

For specified testing of sealing devices. Highly repeatable. A typical application is leak detection of electronic components.

- Vacuum accumulation method:

Automatic detection is easy. With extremely high precision. High repeatability. A typical application is the use of helium mass spectrometer leak detectors in lithium battery leak detection systems.

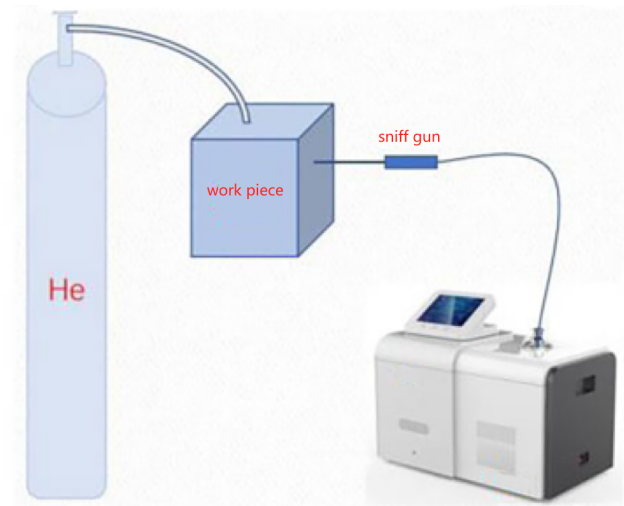

- Normal pressure accretion method of sniffing gun:

Online testing is convenient. No need to vacuum. In the aerospace field, it is often used for leak detection of aerospace transistors.

The above are six commonly used leak detection methods of helium spectrum leak detectors and their common application scenarios.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)