How to detect fire extinguisher leaks with the helium leak detector system?

Why should fire extinguishers be leak tested?

Fire equipment steel cylinders, as special equipment, play a crucial role in the event of a fire. However, due to the fact that these steel cylinders are usually idle and contain high-pressure fire extinguishing materials (usually up to 2.5 MPa) inside, if there is a leak in the cylinder (especially at the weld or valve), especially a small leak, it will pose a great safety hazard. Therefore, it is crucial to conduct strict leak detection procedures on steel cylinders before leaving the factory to avoid leaks during transportation or storage

How to detect fire extinguisher leaks with the helium leak detector system?

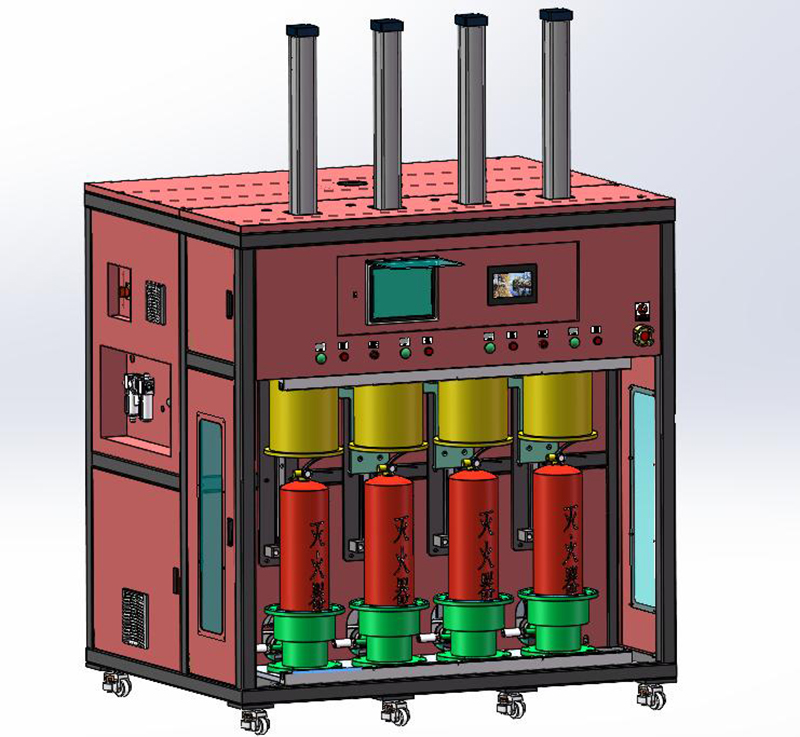

When the number of fire extinguishers to be tested is large, such as 360 fire extinguishers per hour, a single helium mass spectrometer leak detector can no longer meet the requirements, and a helium mass spectrometer leak detector system is required.

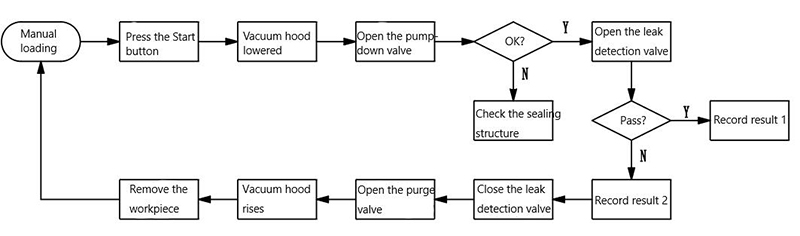

1.Detection process chart

2.Process description

(1)Preparation

Turn on the power switch and start the system. Turn on the compressed air source switch. Adjust the pressure of the pressure reducing valve to the appropriate value, and wait for the system to start up and be ready.

(2)Place the fire extinguisher

Initially, the vacuum hood is in the open state, and the fire extinguisher pre-pressurized with helium is manually placed into the leak detection base.

The leak detection base is equipped with a guide positioning and anti-scratch structure to place the fire extinguisher properly.

The modified structure can adapt to fire extinguishers of different specifications but the same structure. When changing the type of leak detection, it is necessary to replace it according to the diameter of the fire extinguisher.

It should be noted that since the fire extinguisher is filled with helium at a certain pressure before detection, the mouth of the fire extinguisher needs to be purged to remove residual helium before placing it in the leak detection base to avoid misdetection.

(3)Start button

After the workpiece is placed in the inspection station, press the start button, the vacuum hood automatically drops, and the system starts leak detection.

(4)Pre-detect leaks

After the system starts leak detection, open the vacuum valve to pre-evacuate the vacuum hood.

When the pressure of the vacuum hood drops to the set value within the set time, it means that there is no major leakage in the fire extinguisher and vacuum system, and enter the next step of the process.

Otherwise, it means that there is a major leakage or the vacuum hood seal fails. At this time, the equipment will alarm and stop leak detection. The operator needs to press the reset button to check the vacuum cover seal or replace the fire extinguisher.

(5)Detect leaks

After the pressure in the vacuum hood drops to the set value, the system opens the leak detection valve, and the helium mass spectrometer leak detector starts leak detection until the leak detection is completed and the results are recorded.

(6)Feedback on test results

After the fire extinguisher leak detection is completed, the system automatically stops. Then open the purge valve to break the vacuum state in the vacuum hood and remove the helium.

(7)Pick up the fire extinguisher

After removing the helium, the system automatically raises the vacuum hood, please manually picks up the fire extinguisher and places the fire extinguisher according to the leak detection results.

If you are interested in a helium mass spectrometer leak detector system, please contact the EVP team!

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)