Liquid ring vacuum pump working principle

Liquid-ring vacuum pump (also called liquid-ring vacuum pump for short) is a kind of coarse vacuum pump, which can obtain pressure. liquid ring pump can also be used as compressor. It belongs to low pressure compressor. Its pressure range is (1-2) X105Pa gauge pressure (under specific conditions).

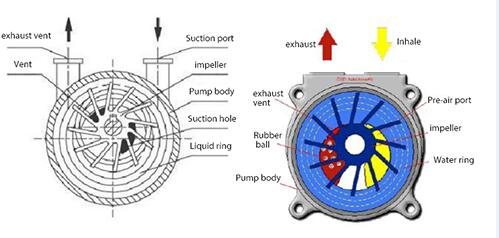

As shown in the diagram of the working principle of the liquid ring pump, the liquid ring pump is composed of impeller, pump body, suction and exhaust disc, liquid ring formed in the inner wall of the pump body, suction port, exhaust port, auxiliary exhaust valve, etc.

The impeller is eccentrically installed in the pump body. When the impeller rotates in the graphical direction, the liquid entering the pump body is thrown around by the impeller. Because of the centrifugal force, the liquid forms a closed liquid ring with the same thickness as the shape of the pump chamber. The upper inner surface of the liquid ring is just tangent to the hub of the impeller (e.g. section I-I), and the lower inner surface of the liquid ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the liquid ring). At this time, a one-month conodont space is formed between the hub and the liquid ring of the impeller, which is divided into several small cavities equal to the number of blades by the impeller. If the starting point is 0 degrees above the impeller, the volume of the small chamber gradually increases from small to large (i.e. from section I-I to II-II) when the impeller rotates 180 degrees before rotation. The pressure decreases continuously and is connected with the suction port on the suction and exhaust disc. When the pressure in the small chamber space is lower than that in the sucked container, the pressure in the small chamber is balanced according to the gas pressure. In principle, the exhausted gas is continuously pumped into the small cavity, which is in the process of inhalation. When the suction is completed, it is isolated from the suction port. From section II-II to section III-III, the volume of the small chamber is gradually decreasing, and the pressure is constantly increasing. At this time, it is in the process of compression. When the compressed gas reaches the exhaust pressure ahead of time, it is exhausted from the auxiliary exhaust valve ahead of time. From section III-III to I-I, the volume of the small chamber connected with the exhaust port further reduces the pressure and further increases. When the pressure of the gas is greater than the exhaust pressure, the compressed gas is discharged from the exhaust port. During the continuous operation of the pump, the process of suction, compression and exhaust is continuously carried out, thus achieving continuity. The purpose of pumping.

In liquid ring vacuum pump, auxiliary exhaust valve is a special structure, usually rubber ball valve is used. Its function is to eliminate the phenomenon of over-compression and under-compression during the operation of the pump. Both phenomena can cause excessive power consumption. Because the liquid ring pump has no direct exhaust valve and the exhaust pressure is fixed, the compression ratio of the liquid ring pump depends on the termination position of the intake port and the starting position of the exhaust port. However, these two positions are fixed and unchanged, so they are not suitable for the need of the change of the inhalation pressure. In order to solve this problem, rubber ball valves are usually installed under the exhaust outlet, so that when the exhaust pressure is reached too early in the pump chamber, the ball valve opens automatically and the gas is discharged, eliminating the phenomenon of over-compression. In general, the suction pressure is used to determine the compression ratio in the design of the liquid ring pump, so as to determine the starting position of the exhaust port, thus solving the problem of insufficient compression.

liquid-ring vacuum pump (hereinafter referred to as liquid-ring pump) is a kind of coarse vacuum pump. The maximum vacuum it can obtain is 2000-4000Pa, and the air ejector in series can reach 270-670Pa. liquid ring pump can also be used as a compressor, known as liquid ring compressor, is a low-pressure compressor, its pressure range is 1-2*105Pa gauge pressure.

liquid ring pumps are used as self-suction pumps, and are gradually used in many industrial sectors such as petroleum, chemical industry, machinery, mining, light industry, medicine and food. In many industrial processes, such as vacuum filtration, vacuum liquid diversion, vacuum feeding, vacuum evaporation, vacuum concentration, vacuum moisture regain and vacuum degassing, liquid ring pumps are widely used. Due to the rapid development of vacuum application technology, the liquid ring pump has been paid attention to in obtaining rough vacuum. Because the gas compression in the liquid ring pump is isothermal, it can extract flammable and explosive gases, in addition, it can extract dust and liquid-bearing gases. Therefore, the application of the liquid ring pump is increasing.

Fig. 1: The pump body is equipped with appropriate amount of liquid as working fluid. When the impeller rotates clockwise in the direction indicated in the figure, the liquid is thrown around by the impeller. Due to the action of centrifugal force, the liquid forms a closed ring which is approximately equal in thickness depending on the shape of the pump chamber. The inner surface of the upper part of the liquid ring is just tangent to the hub of the impeller, and the inner surface of the lower part of the liquid ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the liquid ring). At this time, a crescent-shaped space is formed between the hub and the liquid ring of the impeller, which is divided into several small cavities with equal number of blades by the impeller. If the starting point is 0 degrees above the impeller, the volume of the small chamber increases from small to large at 180 degrees before the impeller rotates, and is connected with the suction port on the end surface. At this time, the gas is absorbed, and at the end of the suction, the small chamber is isolated from the suction port; when the impeller continues to rotate, the small chamber becomes smaller and compresses the gas; when the small chamber and the exhaust port continue to rotate, the gas is compressed. When connected, the gas is discharged out of the pump.

In summary, the liquid ring pump relies on the volume change of the pump chamber to achieve aspiration, compression and exhaust, so it belongs to the variable-volume vacuum pump.

Liquid ring vacuum pump working principle video: https://www.youtube.com/watch?v=YcNICyA7ZwM

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)