Roots blower for sewage treatment

Roots blower for: sewage treatment, flour, aquaculture, pneumatic transport, power, cement and other industries have been widely used. The product air volume scope is wide, divides the file to be close, the boost pressure is high, nearly 20 models, more than 100 kinds of specifications.

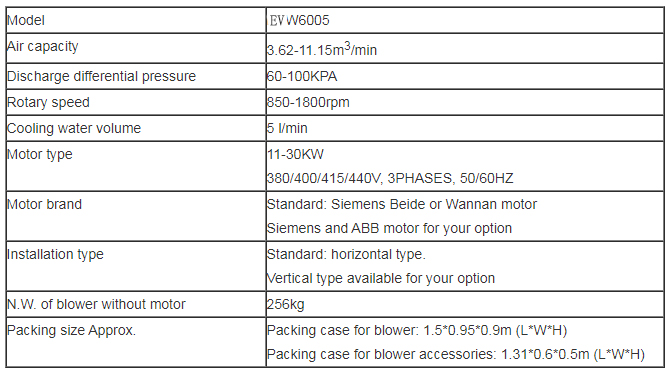

Product specification

Main technical indicators:

Flow rate: 0.5 ~ 46.63m3/min;

Boost: 9.8 ~ 58.8kPa.

Roots blower features:

(1) constant volume fan, no internal compression, the delivery of gas is mandatory, with the change of pressure, the flow change is very small.

(2) the product adopts three-blade straight impeller, with gentle intake and exhaust pulsation and low noise.

(3) the impeller adopts a special curve to make meshing more reasonable, small leakage, high efficiency and low energy consumption.

(4) the product adopts the structural design, making the whole machine compact in structure, small in size, light in weight and elegant in appearance.

(5) the product adopts precision hard tooth surface synchronization.

(6) conveying air is clean, without any oily dust.

Description of technical advantages:

1. Roots fan with negative pressure, roots fan with special gas (piston ring seal, 0 leakage), and dual mechanical oil tank design adopted by the fan to avoid frequent grease contamination.

2, roots fan assembly requirements are very high, the error value of 5-10 wire. The fan performance is missing or serious quality problem is caused by the different sizes of the assembly parts.

3, (according to the size of the fan is not the same) good sealing effect, wear-resistant, durable. Good heat dissipation, more durable. Gear using 20 crmnti (20 cr – mn – ti) gear grinding, precision five

4. Our drive shaft is made of 40Cr. The impeller and the drive shaft are installed as a whole, which can effectively avoid the dissynchronization between the impeller and the drive shaft in the operation of the fan and ensure the running stability of the fan. (the current impeller and shaft installation and fixation technology is hot loading technology. The split-body technology has been gradually phased out, and its stability and durability are weak.

5. Roots fan adopts the screw shape technology at the inlet and outlet, which can effectively reduce the noise of the fan without affecting its performance.

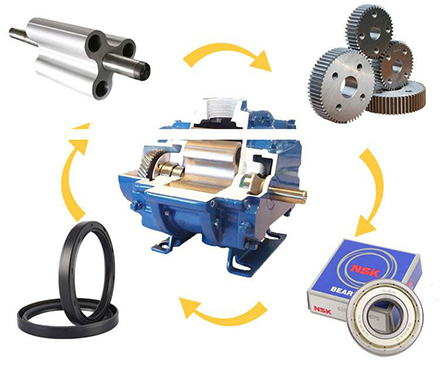

Maintenance of three-leaf roots blower:

(1) daily maintenance: pay attention to the bearing temperature, sound and vibration in daily work, check oil level of oil standard, oil temperature, inlet and exhaust pressure, ammeter index, etc. If conditions allow, replace the gear oil one day after the normal operation of the roots blower. You will find that the oil is dark yellow, dark and sticky. This is because the oil on the bearing, the iron filings in the gear box and the gear oil are mixed together. After the replacement, the replacement shall be conducted once every 3 months.

(2) check every month: the fan with v-belt transmission should check the tension of v-belt regularly.

(3) quarterly inspection: clean the filter regularly and replace the gear oil once a quarter.

(4) annual inspection: the gear, bearing, oil seal and gas seal of the fan shall be cleaned regularly every year. Check the internal conditions of the rotor and cylinder, and correct the clearance of each part.

Roots blower product display

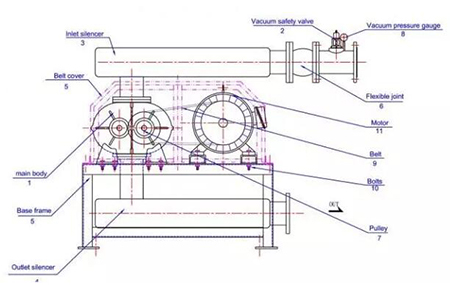

Assembling drawing