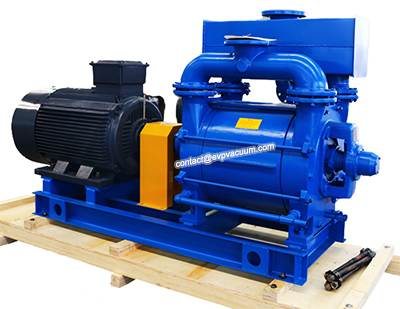

water ring vacuum pump material delivery

Is it better to use jet device or water ring vacuum pump for material conveying?

At present, pneumatic jet, a kind of powder conveying device, has appeared in the market, and how powerful its claimed function is. The principle of its use is to use the “Venturi principle” jet principle to drive the pipeline gas flow through high-pressure gas to form a vacuum, so it can suck and send powder.

However, the application of jet device has low vacuum degree, low suction and delivery height, high gas consumption and low efficiency.

The water ring vacuum pump is very practical in material transportation. Many people don’t understand the installation points of the water ring vacuum pump and the requirements of the material transportation pipeline. By collecting the actual requirements of users, we have designed a variety of water ring vacuum pump material transportation systems, which are simple, convenient, environmental friendly and fully adapt to the needs of material transportation in various industries.

water ring vacuum pump material conveying characteristics :

1. The equipment is simple in structure, easy to manufacture, process and install, low in control cost and short in establishment time. The main part of the water ring vacuum pump system is the welding structure of the section steel plate, which is composed of the components with the shape of the pipe and the tank. The relative movement and maintenance operation between the components are relatively easy. If some control equipment is added, it is easy to complete the automatic operation.

2. High efficiency of guarantee and no return transportation of equipment. Other means of transport have the defect of empty return, while the transport medium of water ring vacuum pump is air, which only needs to be discharged into the atmosphere at the terminal. In the process of guarantee, the feed port can be continuously fed to complete the continuous guarantee.

3. The sanitary operation conditions are good. When the water ring vacuum pump is operated in the pipe, the material is in the negative pressure, the dust will not leak and fly, and the material will not fly and pollute the environment. In the process of transportation, it can also stop sorting, boring and other intermediate disposal. For example, if the materials are transported under negative pressure, because the water is easy to evaporate under negative pressure, even if other dry methods are not used, the materials with higher water content will also have a certain dry effect in the process of transportation. With the different weight of material particles, the proper unloading port can be designed to separate the materials.

4. In addition, the water ring vacuum pump’s delivery pipeline is convenient for setting up the pipe network according to the needs of the body, and the layout is cumbersome and sensitive, which can fully utilize the air accumulation in the field and be easy to adapt to the working environment.

To sum up, the vacuum transportation of water ring vacuum pump has the characteristics of simple operation, high delivery efficiency and good operation sanitary conditions. During the vacuum transportation, it can not only effectively improve the gas transportation efficiency and the cleanliness of the surrounding environment, but also improve the quality and use efficiency of the gas transportation.