Liquid Ring Vacuum Pumps in Egg Tray Industry

Application of EVP 2BE and DLV Series Liquid Ring Vacuum Pumps in Egg Tray Industry

With the continuous development of the pulp molding industry—particularly the rapid growth in eco-friendly packaging and disposable paper products—the liquid ring vacuum pump has become increasingly important in the forming process as a core vacuum generation device. EVP’s 2BE and DLV series liquid ring vacuum pumps, with their high pumping speed, strong vacuum capability, and durability, are becoming the preferred equipment for many egg tray production enterprises.

I. Specific Applications of Liquid Ring Vacuum Pumps in the Egg Tray Industry

1. Suction Molding Stage

In egg tray production, pulp is formed into its initial shape through suction onto a forming mold. The liquid ring vacuum pump creates negative pressure by drawing vacuum inside the mold, enabling the fiber-rich pulp to adhere to the mold surface and form the egg tray preform. This process requires a high level of vacuum.

Pump Functions:

(1) Provide a stable and efficient vacuum environment

(2) Ensure even pulp distribution and improve forming precision

(3) Shorten suction time and enhance production efficiency

2. Dehydration and Mold Transfer Process

The freshly formed wet egg trays contain high moisture and must undergo initial vacuum dehydration before being transferred to the drying line. The liquid ring vacuum pump continues to extract air, helping to remove free water from the mold.

Pump Functions:

(1) Accelerate dehydration and reduce drying load downstream

(2) Prevent deformation or damage during mold transfer

(3) Improve overall production line flow efficiency

3. Energy-Efficient Centralized Vacuum System

Large-scale pulp molding production lines usually include multiple forming machines. Liquid ring pumps can be integrated into a centralized vacuum station to supply vacuum to multiple workstations simultaneously. Using frequency converters and buffer tanks, energy consumption and equipment investment costs can be significantly reduced.

Pump Functions:

(1) Lower energy consumption per unit of product

(2) Avoid redundant equipment investment

(3) Enhance workshop management and operation efficiency

4. Adaptation to Harsh Conditions and Prolonged Service Life

Pulp molding environments are humid and contain pulp impurities, with frequent ingress of mist and fiber particles into the vacuum system. Liquid ring pumps use liquid (usually water) as the working medium, offering excellent corrosion resistance and impurity tolerance, making them ideal for this industry.

Pump Functions:

(1) Operate stably in high-humidity, particle-laden environments

(2) Reduce risk of system blockage

(3) Lower maintenance frequency and spare part costs

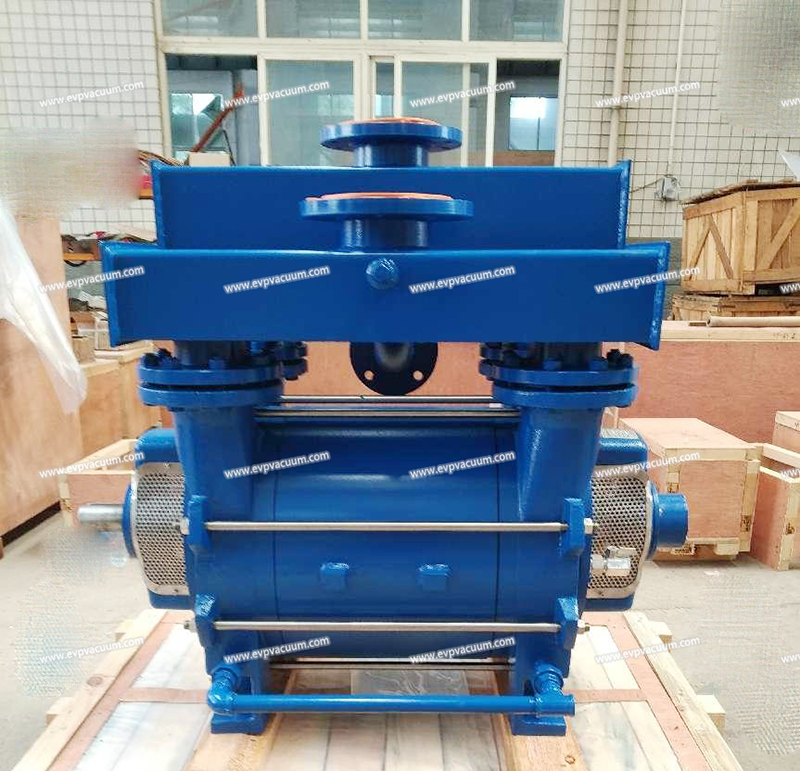

2BE series Liquid Ring Vacuum Pump

DLV series Liquid Ring Vacuum Pump

II. Advantages of 2BE and DLV Series in the Egg Tray Industry

1. High Pumping Speed and Stable Vacuum – Ideal for Medium to Large Production Lines

(1). 2BE: Wide pumping range (up to 400–3000 m³/h), suitable for simultaneous operation of multiple forming stations.

(2). DLV : Dual-stage structure, more stable pumping and higher ultimate vacuum (up to -0.096 MPa), especially ideal for applications requiring minimal vacuum fluctuation (e.g., thin-walled egg trays or lunch boxes).

2. Adapted for High-Moisture, Pulp-Rich Environments – No Clogging or Pump Failure

The internal liquid sealing system of both 2BE and DLV series allows them to handle vapor-laden and pulp-containing gases. Resistant to hot and humid conditions, they greatly reduce clogging caused by pulp residue. Shaft sealing options include durable mechanical seals or packing seals to prevent pulp back flow, ensuring long-term pump operation. Available in cast iron or stainless steel for extended lifespan.

3. Stable structure, supporting all-weather continuous operation

EVP’s 2BE and DLV series feature heavy-duty industrial designs with low noise, minimal vibration, and excellent continuous operation capacity. Ideal for 24-hour production in egg tray plants, they minimize maintenance downtime and improve overall uptime.

4. Energy Efficiency – Lower Operating Costs

Can be paired with EVP’s dedicated variable frequency control systems to adjust vacuum output on demand, preventing energy waste. The dual-stage DLV series improves energy efficiency by 15%+ in high vacuum zones compared to traditional single-stage pumps, especially beneficial during summer when pulp moisture content and gas load fluctuate greatly.

5.Versatile Application: Covers Suction, Dehydration, and Demolding in One System

6.Industry Recognition: Proven in Many Overseas Egg Tray and Pulp Molding Projects. Received positive feedback from customers worldwide for performance and reliability.

III. Conclusion

EVP’s 2BE and DLV series liquid ring vacuum pumps, with their high pumping speed, excellent vacuum performance, and superior wet-pulp tolerance, have become key equipment in the egg tray production process. Their robust structure (e.g., heavy-duty bearings, corrosion-resistant pump bodies) and intelligent energy-saving control (e.g., frequency conversion, dual-stage pumping) offer both performance and cost advantages. They are suitable for all processing stages, from single-machine suction forming to large-scale centralized vacuum systems. Proper model selection based on mold count, forming speed, and pulp properties ensures triple benefits of increased capacity, reduced energy consumption, and improved equipment reliability.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)