vacuum pumps in printing industry of application

This article mainly describes the application details of vacuum pumps in the printing industry. Due to the special mechanical properties of paper, many printing jobs can only be completed with the help of vacuum and compressed gas.

1. Application of vacuum pumps in printing industry

(1) Paper cutting table

(2) Rotating rod and rotating table

(3) Central vacuum system

(4) Screen printing machine

(5) Printing powder

(6) Book binding machine

(7) Digital printing

(8) High-performance copying

(1) Paper cutting table

The use of air cushions makes it easy to move and straighten the paper pile when cutting. To this end, the paper cutting table has a built-in nozzle, which is sealed with a spring-loaded ball. The weight of the paper pile placed on the ball can open the nozzle and release the compressed air under the paper.

(2) Rotating rod and rotating table

For duplex printing, the paper web must be turned over on appropriate turning bars or tables. This is done by blowing air through a perforated tube, which creates an air cushion. The paper web can then slide over the air cushion without coming into contact with any surface. After printing is complete, a similar air cushion ensures that the printed paper web is dried and stacked without smudging the wet ink.

(3) Central vacuum system

Many printing processes require vacuum or compression, including printing, folding, alignment, binding, cutting, packaging and labeling. There is no need to provide a vacuum pump for each individual production equipment. The central vacuum system can provide the required vacuum for all individual equipment, thus saving space in the production area and reducing employees’ exposure to noise and heat. The central vacuum system uses several compressors and can be repaired without interrupting production because other compressors in the system can take over the work of the failed machine. In addition, the application of the central vacuum system can be optimized and economical by selectively turning on and off individual compressors.

(4) Screen printing machine

a. Forced drying of the printing blocks: During the printing process, the vacuum pump helps to force drying of the printing blocks by generating negative pressure, thereby improving production efficiency

b. Ensure the accuracy and precision of printing: The vacuum pump can also play a positioning role on the screen printing machine, effectively ensuring the high accuracy and precision of printing, thereby ensuring the efficiency of printing

c. Reduce noise and overheating problems: Using a vacuum system can reduce noise in the workshop and will not overheat in the summer, thereby saving air conditioning power

(5) Printing powder

During the printing process, the paper needs to be accurately delivered to each printing frame. At this time, a vacuum pump is needed to control the adsorption force and transfer speed to ensure that the paper can be firmly fixed on the paper feeding system, thereby ensuring its stability and accuracy during the transmission process.

(6) Book binding machine

Vacuum pumps are mainly used for vacuuming and sealing in book binding machines. Through vacuuming, the pages are tightly bound together to ensure that the pages will not move or misalign during the binding process, thereby improving the binding quality.

(7) Digital printing

a. Paper adsorption system: During the printing process, the paper needs to be in close contact with the surface of the machine to ensure the accuracy and stability of printing. The Roots vacuum pump uses its powerful vacuum adsorption capacity to ensure that the paper is completely attached to the printing platform, thereby improving the accuracy and stability of printing.

b. Printing plate cleaning system: During the printing process, the printing plate is prone to adhere to ink and pigments, affecting the printing effect. The Roots vacuum pump uses negative pressure adsorption to thoroughly remove stains on the surface of the printing plate, improve cleaning efficiency, and reduce downtime.

c. Waste paper cleaning system: Waste paper generated during the printing process needs to be efficiently handled. The Roots vacuum pump uses negative pressure adsorption technology to automatically suck waste paper into the equipment and store it, improving the efficiency of waste paper cleaning.

(8) High-performance copying

a. Reduce gas interference: During high-performance copying, the vacuum pump reduces the gas pressure in the container to reduce the interference of gas molecules on the copying process, ensuring the accuracy and stability of the copy.

b. Improve copy quality: In a low-pressure environment, the activity of gas molecules is reduced, reducing the error caused by gas flow, thereby improving the quality and accuracy of the copy.

c. Maintain a stable environment: The vacuum pump can maintain a stable low-pressure environment to ensure that the parameter changes during the copying process are within a controllable range, avoiding copy failures or quality problems caused by pressure fluctuations.

2.What vacuum pumps can be used in the printing industry?

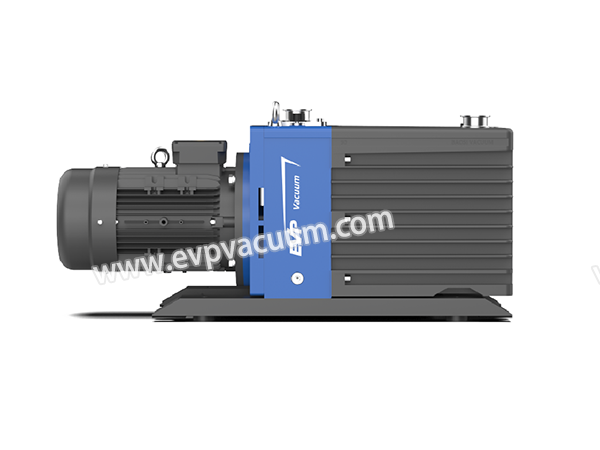

(1) Rotary vane vacuum pump: It runs smoothly and has low noise. It is suitable for use in the adsorption filtration and belt adsorption of printing machines.

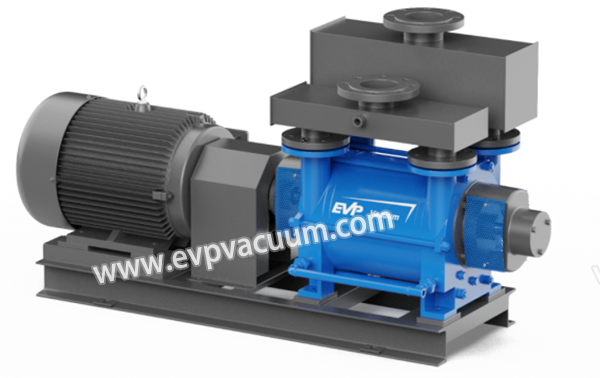

(2)Liquid ring vacuum pump: It has a simple structure and is easy to maintain, but it needs to pay attention to corrosion protection. It is suitable for certain special printing materials or environments.

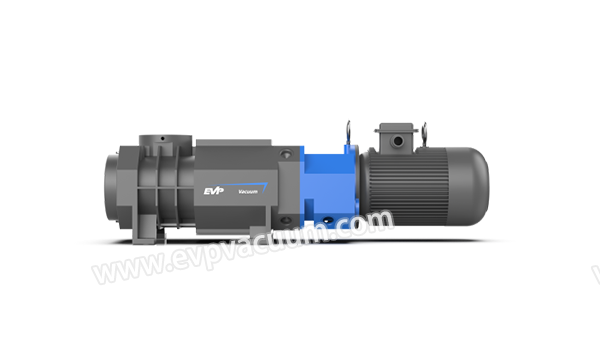

(3)Dry screw vacuum pump: It has no oil pollution, low noise and low vibration. It is suitable for printing environments with high cleanliness requirements.

(4) Oil-free rotary vane vacuum pump: Oil-free rotary vane vacuum pump is also suitable for the printing industry. It has the advantages of environmental protection, high efficiency and low noise.

The choice of these vacuum pumps depends on the specific printing process and usage scenario. If you need more information, please contact the EVP team.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)