Metal surface processing water ring vacuum pump

Metal surface processing industry:

In processing industry like thin plate polishing, grinding and engraving, and other processes, the previous methods are to clamp the bag or magnetically hold the workpiece, which is easy to deform and difficult to clamp. The tooling is difficult to design and manufacture, and the stainless steel cannot be held magnetically. Vacuum adsorption can just avoid the above problems, and is convenient and simple.

In the past, many manufacturers used rotary vane, piston, and slide valve vacuum pumps. Due to the water and powder in the processing process, it is easy to deteriorate or jam the vacuum pump oil, causing equipment damage and changing the oil every day. The use cost is extremely expensive. Monthly maintenance, and replacement is needed about every half a year.

The water ring vacuum pump does not have these shortcomings. Facts have proved that the water ring vacuum pump used in the processing industry is efficient, energy-saving, durable and simple.

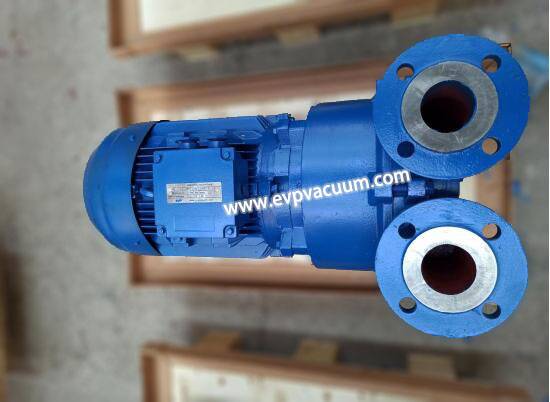

Water ring vacuum pumps in this processing industry are generally used: 2BV, 2SK, etc.

2BV series water ring vacuum pumps are small in size and convenient to move; high efficiency and energy saving;

2SK series water ring vacuum pumps are made of alloy, which is not easy to rust; the structure is simple and easy to maintain; it has good airtightness, environmentally-friendly and sanitation.

Edited by: Shanghai EVP Vacuum Technology Co., ltd

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)