molecular pump in semiconductor of application

Silicon carbide (SiC) is very rare in the natural environment. It was first discovered in meteorites in the solar system 4.6 billion years ago, so it is also called “semiconductor material that has experienced 4.6 billion years of time travel.” Compared with traditional silicon devices, SiC devices have advantages in switching speed, breakdown field strength, band gap, electron saturation speed, melting point, and thermal conductivity.

![]()

Silicon carbide is a compound semiconductor material composed of carbon and silicon. And gallium nitride (GaN), aluminum nitride (ALN), gallium oxide (Ga2O3), etc., are collectively referred to as wide-bandgap semiconductor materials due to their band gaps greater than 2.2eV, and are also called third-generation semiconductor materials in China.

SiC semiconductor materials have excellent properties, especially as components for power conversion and control. Compared with traditional silicon devices, they can work stably under low on-resistance, high-speed switching, and high temperature and high pressure resistance, so they are popular in power supplies, automobiles, railways, industrial equipment, and household consumer electronics.

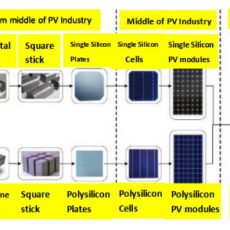

![]()

Performance comparison of silicon carbide (SiC) and silicon (Si)

With the development of electric and hybrid vehicles, SiC is also rapidly emerging in this field, involving industries including energy (PV, EV charging, smart grid), automobiles (OBC, inverters), infrastructure (servers), etc. In addition, power storage and charging stations are also target markets. Silicon carbide power devices provide a wide range of on-board application solutions for electric vehicles and hybrid vehicles, and are mainly used in on-board chargers, step-down converters and main drive inverters.

Another application of SiC is photovoltaic power generation, mainly solar inverters, which are only half the size of IGBT-based solutions. The faster switching speed of SiC means that manufacturers can reduce the size of passive components in the system, large capacitors and transformers can be miniaturized, and the size of the heat sink can also be reduced. As system efficiency increases, energy capture can be maximized .

As a molecular pump professional manufacturer in China. EVP Vacuum has formed an indissoluble bond with silicon carbide, helping domestic industrial equipment manufacturers to promote SiC process upgrades, research and development and production of higher performance SiC single crystals and devices, and is committed to creating rich and beautiful life.

EVP Vacuum focuses on the silicon carbide market and provides industry-specific vacuum solutions including industry-specific molecular pumps, mechanical pumps and plug-in valves. At the same time, in order to meet the continuously upgraded product technology and process requirements, EVP Vacuum can provide customization according to application requirements We provide customized service solutions to provide the best vacuum solutions for different customers.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)