vacuum pump in the production of monocrystalline silicon of application

Monocrystalline silicon generally refers to a substance formed by an arrangement of silicon atoms.

The conductivity of semiconductors is between conductors and insulators. Silicon, germanium, gallium arsenide and cadmium sulfide are all semiconductor materials. The resistivity of semiconductor materials decreases with increasing temperature and radiation intensity. In semiconductors Adding a small amount of impurities has a decisive influence on its conductivity, which is an important characteristic of semiconductor materials. Silicon is the most common and most widely used semiconductor material. When molten elemental silicon is solidified, silicon atoms are arranged in a diamond lattice to form crystal nuclei, and the crystal nuclei grow into crystal grains with the same crystal plane orientation to form monocrystalline silicon.

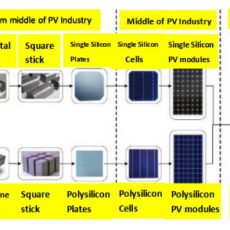

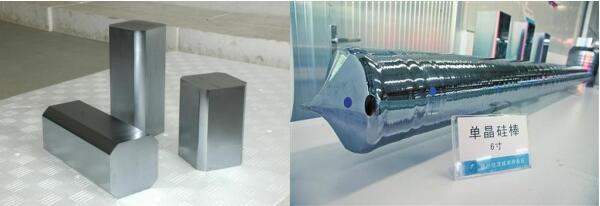

As a relatively active non-metal element crystal, monocrystalline silicon is an important part of crystalline materials and is at the forefront of the development of new materials. The production of monocrystalline silicon materials goes through the following processes: quartz sand-metallurgical grade silicon-purification and refining-deposition of polycrystalline silicon ingots-monocrystalline silicon-wafer cutting. Its main purpose is to be used as a semiconductor material and the use of solar photovoltaic power generation, heating, etc.

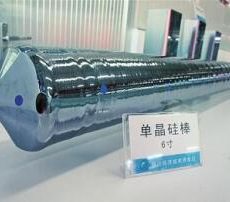

In the production process of monocrystalline silicon, the monocrystalline furnace (see the figure below) needs to be vacuumed with a vacuum pump to keep the monocrystalline furnace in a high vacuum state to remove excess harmful gases, and then fill with inert gas As a protective gas. Afterwards, the graphite heater in the monocrystalline furnace is used to heat and melt the bulk polycrystalline silicon material placed in the quartz crucible to complete the production of monocrystalline silicon. Vacuum and continuously fill with inert protective gas.

In the production of monocrystalline silicon, the slide piston vacuum pump has become the most commonly used vacuum pump in the industry due to its stable pumping speed and relatively high vacuum. The piston vacuum pump produced by Shanghai EVP Vacuum Technology Co., Ltd. has been widely used in this industry, and has developed close cooperation with domestic and international monocrystalline silicon manufacturers, such as model 2H-150, 150L/s, and ultimate vacuum of 0.06Pa; Customers have higher and higher requirements for environmental protection and clean vacuum. At present, some customers also use dry screw pumps to produce monocrystalline silicon. For specific questions, please contact our sales department.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)