Roots Dry Screw Vacuum Pump unit used in Photovoltaics industry

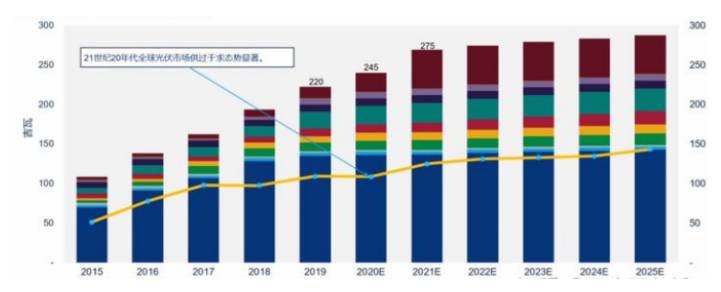

According to statistics, in 2020, the production capacity of Chinese polysilicon materials enterprises is about 470,000 tons, and the overseas production capacity is about 5,000 tons. The output of polysilicon materials in 2020 is expected to be about 390,000 tons, and the annual polysilicon imports are about 92,000 tons.

Compared with 2019, the output of polysilicon in 2020 will be reduced by 100,000 tons. Based on the installed capacity of 140GW next year, the silicon material is short of 15,000 tons under a relatively conservative estimate. The supply and demand relationship of silicon material next year is relatively optimistic; it is expected that silicon material will be in 2020 The production capacity of wafers is 200GW, including 140GW for monocrystalline silicon wafers and 60GW for polycrystalline silicon wafers; 180GW for PERC cells; and 220GW for modules.

In 2021, the demand side of photovoltaics is expected to add 47GW in China, and the installed capacity from 19 and 20 to 21 years is 15GW, and the total installed capacity of photovoltaics is 62GW. It is estimated that the global installed capacity will be 150GW that year. The gap between the supply side and the demand side is pulled

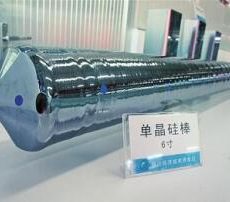

Semiconductor industry is highly prosperous, and Chinese dry vacuum pump is continuously deepened to replace oversea brands, Monocrystalline silicon has ushered in explosive growth and the upgrading of photovoltaic industry, the installed capacity of photovoltaic continues to grow steadily and, The major silicon wafer enterprises speed up the production expansion progress, which all promoted the development of vacuum pump and peripheral products. Due to the high quality, efficient and clean performance of Shanghai EVP vacuum dry screw vacuum pump advantage performance, which have been widely used Battery production has played an important role and favored by various processes of crystalline silicon, CdTe, CIG and silicon thin film technology, as well as photovoltaic technology, so Shanghai EVP vacuum pumps sales continue to rise.

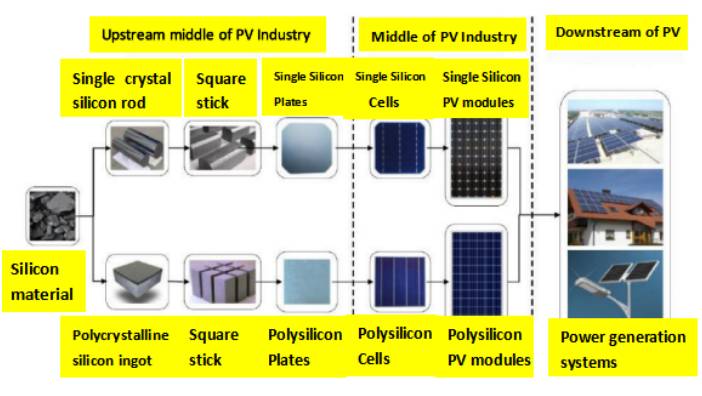

Here we briefly describe the production process involved in the whole photovoltaic industry, as shown in the figure;

The production of solar cells: from the production of silicon crystals and solar cells to the stacking of solar modules, the production process of these series is inseparable from the development of vacuum technology. The production of crystalline or thin film coating, customized vacuum solution is a key factor in photovoltaic production.

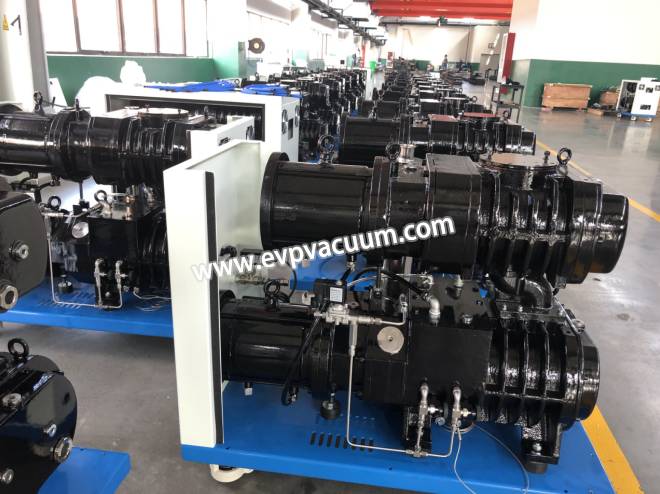

In the lamination process of solar cells: it is very important to package the solar cells and connect the front and rear protection plates at the same time. In order to achieve the best results, Shanghai EVP VACUUM has customized the dry screw vacuum pump for customers, and the pumping speed of the vacuum pump is perfectly matched with this application. The roots-dry screw vacuum pump unit is specially designed for this industry. This system is optimized to deal with the by-products produced in the lamination process. It is favored by customers for its efficient operation time, extremely low maintenance cost, high vapor resistance and particle compatibility, easy on-site cleaning, low operation cost, free maintenance and extended service interval .

In order to meet the market demand, Shanghai EVP vacuum has expanded 8 production plants to only produce roots pump, screw pump and Rotary Piston Vacuum pump, covering an area of 46179m3, TOP 1 in whole Chinese vacuum pump’ market, pictures for your reference as follow:

Editor by: Shanghai EVP vacuum Co., Ltd

Key words: Roots vacuum pump, Roots -Dry screw vacuum unit, oil free screw pump, Rotary Piston vacuum pumps, PV Production vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)