Brand: EVP

Classification: Vacuum Pump

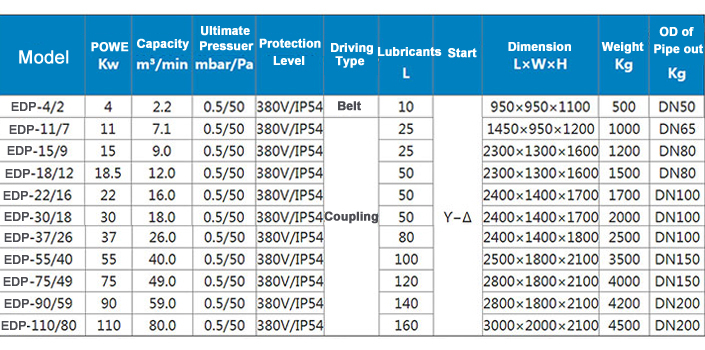

SUCTION CAPACITY:2.2L/S TO 80L/S

VACUUM RANGE: 0.5MBAR-50MBAR

Availability : In Stock

Low Rotor Ratation Speed, General Motor, Soundproof Enclosure, Efficient Oil Separator, Oil Can Be Set Thermostats.

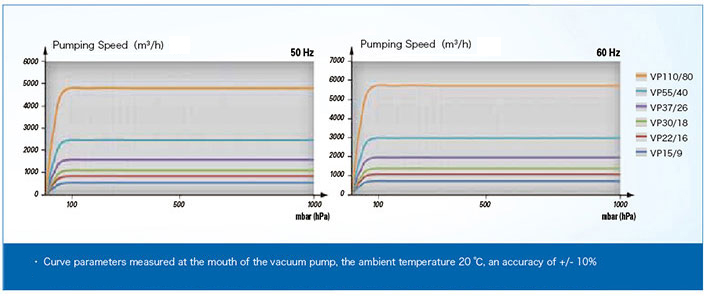

Oil seal screw vacuum pump performance curve:

Oil Seal Screw Vacuum Pump Features:

Low Rotor Ratation Speed

EVP low pressure screw air compressor adopalt ensure EDP series vacuum pump is extremely quiet-Produc ts for the lowe st noise 69dB(A)-it can be installed next to the pump around the operator’s main device,Ensuring high relibility and long life cycle of the products. high efficient oil-air separation system. Ensuring that the products, of high reliability and long life cycle.oil content of the compressed air under 3 ppm.

General Motor

EDP vacuum durable, high reliability and comfigured servo motor features high coe fficient of ensuring a long product life;

Vacuum Pump Air Inlet Dirctly Mounted Modular Valve;

It enables the device to adjust according to the actual needs of the product preformance;

Reduce the impact of fluctuations in the operation of the device on the system;

By reducing the product starts/stops, reduced wear and shorten product maintenance cycle.

Soundproof Enclosure

The noise levels to a minimum 69dB(A), Optimize the product appearance.

Efficient Oil Separator

Filter easily replaced, reducing reflux and optimize, product performance;

With minimal maintenance times to ensure product life;

Allow product near atmospheric pressure range, acoid installing additional accessories.

Oil Can Be Set Thermostats

Avoiding condensation of water, particularly in a specific environment, pollution tank;

For wet application on the compressor element of condensate, provide continuous performance.

Oil seal screw vacuum pump application:

Electronics, plastic, lithium batteries, printing and packaging industries.

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.