Vacuum system in vacuum pressure painting impregnation

Application

Vacuum pressure painting impregnation equipments are mainly applied to the insulation processing of electrical products, such as high-voltage motors, traction motors, wind turbines, water turbines, explosion-proof motor, coal dedicated transformer, H class insulation dry-type transformers, power capacitors, cable insulation material dipping. Excellent insulation could be guaranteed with these equipments. Water and gas which affect insulation a lot are pumped in the vacuum processing. And insulated painting penetrates very deep into the material in the painting processing, which strengthen and improve insulation.

Vacuum pressure painting impregnation equipments are also applied to material industry like graphite products, precision engine castings, refractory bricks etc.. Material structure could be modified by these equipments to improve material performance. Fox example, graphite will be harder and more resistant when a greater density is obtained by vacuum pressure painting impregnation. Micro-leakage will be avoided when automotive engine castings or high-pressure valves are formed by using these equipments. Refractory brick performance will be changed as expect if they are impregnated with different impregnants (such as asphalt, preservatives, etc.)

Working principle

When work pieces are put into a vacuum pressure vessel, vacuum pump systems for vacuum pressure painting impregnation start to work and pump up water and gas so that the impregnant injected into the vessel by pressure difference or transmission pumps could penetrate completely these work pieces under certain motivating pressure.

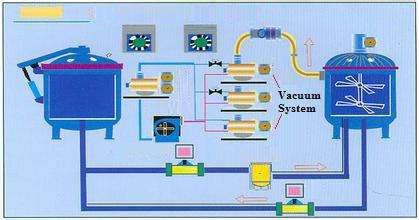

Vacuum systems for vacuum pressure painting impregnation

Vacuum systems are used to pump gas and water in three main parts of a vacuum pressure painting impregnation equipment, painting-dipping tank, painting-storage tank and painting-drying tank. Whether gas and water are pumped up or not determines directly the impregnation processing performance. Therefor a vacuum system is vital for vacuum pressure painting impregnation.

The vacuum system for vacuum pressure painting impregnation which is chosen very often for this processing is a mix model of roots vacuum pump+liquid ring vacuum pump, for example, JZJS300-21P vacuum systemwhich is made up of one ZJ300, one ZJ150A and one 2SK-6A.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)